In the wake of increasing environmental concerns and the urgent need for sustainable solutions, pulp molding machines are gaining prominence as a cornerstone in the production of eco-friendly packaging products. These machines, which utilize recyclable waste paper to create various types of molded pulp products such as egg trays, fruit trays, and eco-friendly packaging materials, are leading the charge towards greener manufacturing processes. This article explores the technology behind pulp molding machines, their applications, benefits, challenges, and the future potential of this burgeoning industry.

Understanding Pulp Molding Technology

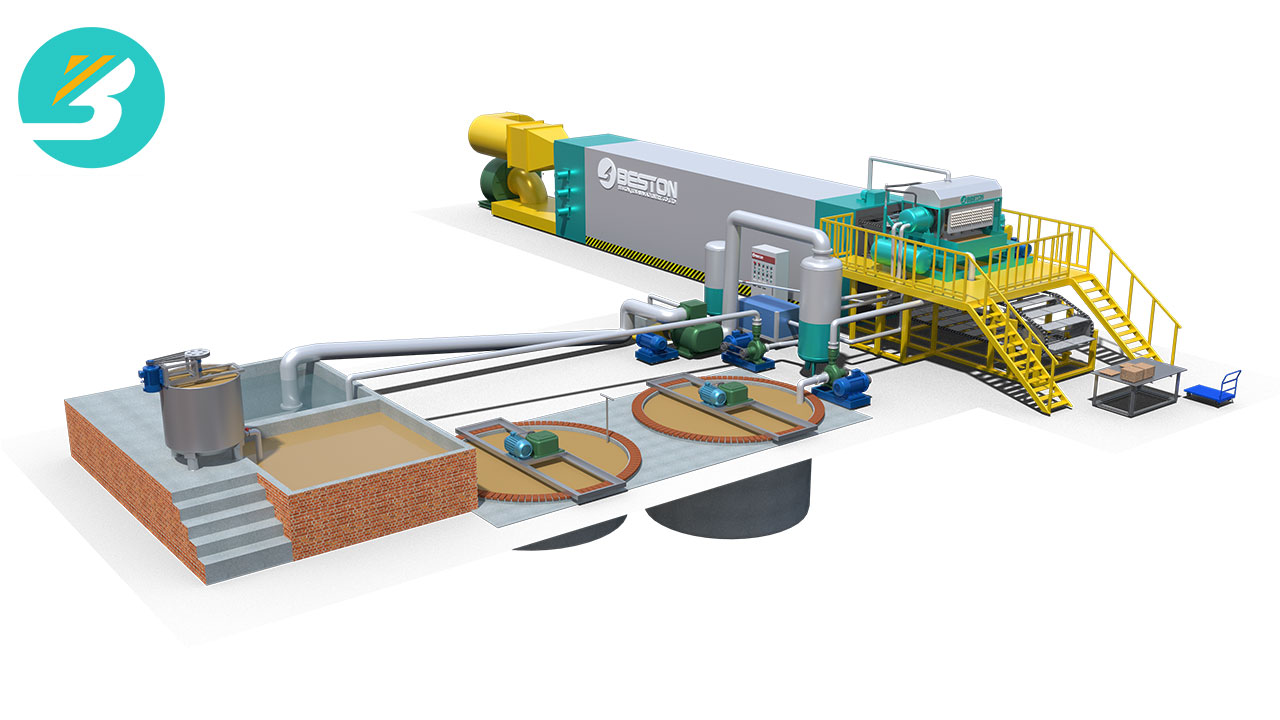

Pulp molding is a process of pulp molding machine that involves converting recycled paper fiber into a malleable pulp that is then shaped into specific forms using specialized machines. The basic steps in the pulp molding process include pulping, molding, drying, and sometimes pressing and trimming.

- Pulping: Recycled paper is mixed with water in a hydropulper to form a slurry. This slurry is then refined to achieve the desired consistency before additives like waterproofing agents or coloring dyes are introduced.

- Molding: The pulp is transferred to the molding machine where vacuum suction and heat are applied to form it into specific shapes according to the mold designs. This is the core stage where the pulp takes the shape of the final product.

- Drying: After molding, the wet pulp products are passed through a drying line, which can be operated by heat generated from different sources, including conventional fuels, gas, or electricity, and increasingly, through more sustainable means such as solar energy.

- Pressing and Trimming: Some high-end pulp molding machines include additional stages where the molded products are pressed to enhance their density and surface smoothness. Trimming helps in removing excess edges, improving the aesthetic and functional quality of the products.

Applications of Pulp Molding Machines

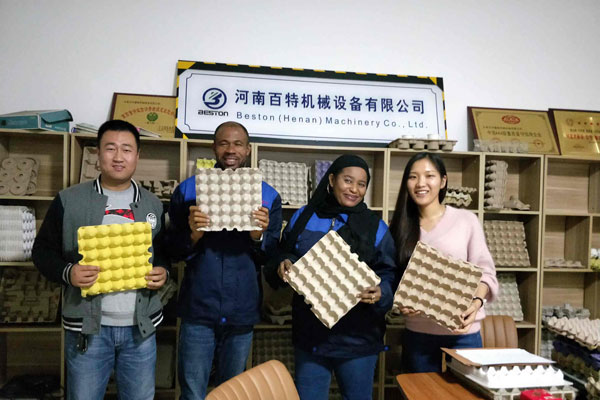

Pulp molding machines are incredibly versatile, capable of producing a wide range of products depending on the mold specifications. Common applications include:

- Packaging Solutions: Producing packaging for eggs, fruits, wine bottles, and medical products. These packaging solutions are favored for their biodegradability and shock-absorbing properties.

- Disposable Products: Such as plates, cups, and other catering disposables, which are becoming increasingly popular alternatives to plastic products due to their compostability.

- Custom Packaging: High precision molds of egg tray machine can create custom packaging shapes for electronics, cosmetics, and other retail products, offering both protection and a reduced environmental footprint.

Environmental Benefits

The shift towards pulp molding technology offers significant environmental advantages:

- Reduction of Waste: By using recycled paper and cardboard, pulp molding helps in significantly reducing waste that would otherwise end up in landfills.

- Biodegradability and Compostability: Unlike plastic, molded pulp products are 100% biodegradable and compostable, which significantly reduces their environmental impact after disposal.

- Energy Efficiency: Modern pulp molding machines are designed to be energy-efficient, often incorporating advanced drying techniques that minimize energy consumption.

- Water Recycling: The pulping process includes water treatment systems that allow for the reuse of water, thereby minimizing water wastage.

Challenges and Innovations

Despite its many benefits, the pulp molding industry faces several challenges. The initial setup cost for a pulp molding production line can be high, deterring small and medium enterprises. Additionally, the drying process is energy-intensive, and if not managed properly, can negate some of the environmental benefits.

In response to these challenges, there are ongoing innovations aimed at making pulp molding tableware machine more efficient and less resource-intensive. These include:

- Enhanced Drying Techniques: Development of more energy-efficient drying systems using alternative energy sources.

- Automation: Integrating AI and robotics to streamline the production process, reduce labor costs, and increase output efficiency.

- Improved Mold Designs: Using 3D printing technology to create more precise and variable mold designs that can reduce waste and energy usage.

The Future of Pulp Molding Machines

Looking forward, the pulp molding machine industry is set to expand as the demand for sustainable packaging solutions continues to rise. With ongoing research and technological advancements, these machines are expected to become more efficient, affordable, and accessible. This will not only benefit the environment but also offer businesses a competitive edge by aligning with consumer preferences for sustainable products.

The expansion of global markets for biodegradable products will likely drive further investments into pulp molding technology, ensuring that this innovative approach to sustainable packaging continues to grow and evolve. As industries seek greener alternatives, pulp molding machines will play a critical role in the transition towards more sustainable manufacturing practices, making them a key player in the global effort to foster a more sustainable future. Find a high quality egg carton making machine here.