In the ever-evolving landscape of waste management and sustainable technologies, continuous pyrolysis plants have emerged as a key player in converting various organic materials into valuable resources while minimizing environmental impacts. This post aims to shed light on the continuous pyrolysis equipment, exploring its functionality, environmental benefits, versatile applications, and its role in shaping a more sustainable future.

The Waste Challenge

The world faces an escalating waste crisis, with traditional disposal methods falling short. This chapter outlines the pressing need for innovative waste management solutions, emphasizing the environmental and social consequences of inadequate waste handling.

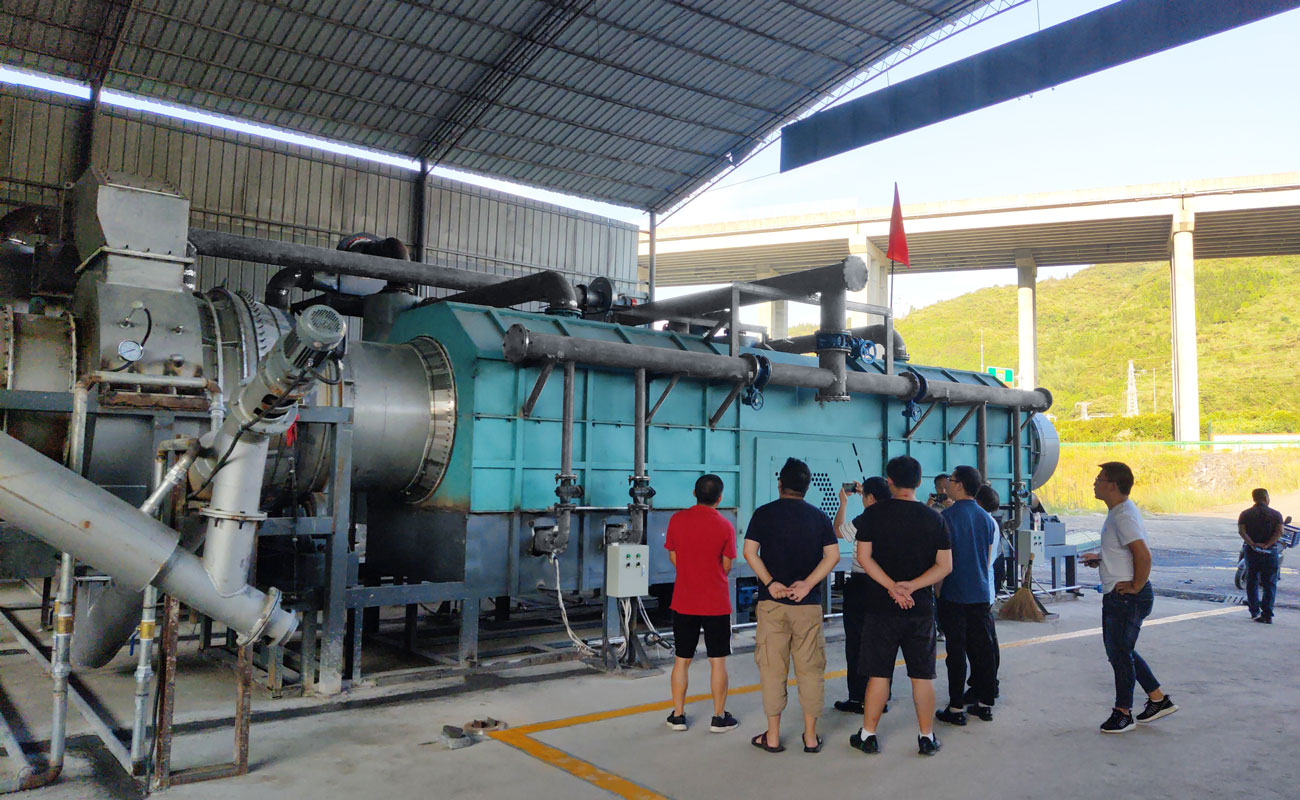

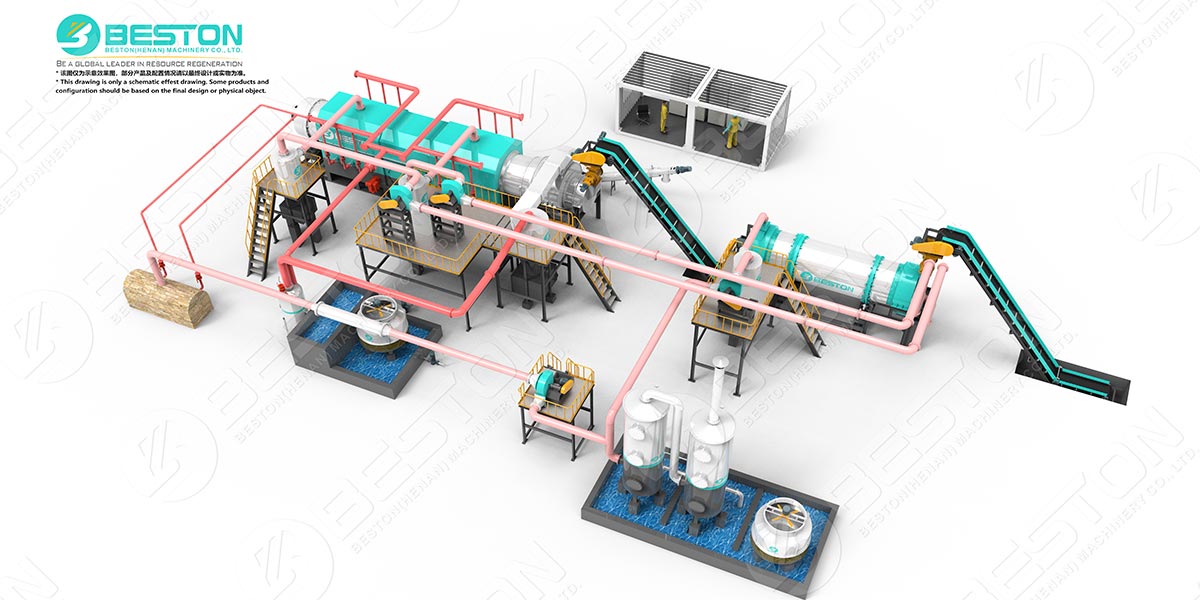

Continuous Pyrolysis: A Sustainable Approach

At the core of addressing the waste challenge is continuous pyrolysis, a process that harnesses heat in the absence of oxygen to convert organic materials into valuable end-products. This chapter provides a detailed look at how continuous pyrolysis works and its significance in waste transformation. The small scale pyrolysis plant has small capacity.

The Outputs of Continuous Pyrolysis

Continuous pyrolysis plants yield three primary outputs: pyrolysis oil, carbon black, and syngas. This chapter explores the composition, properties, and various applications of these valuable products.

Environmental Stewardship

Continuous pyrolysis plants are renowned for their environmental benefits. This chapter delves into the eco-friendly aspects of the technology, including waste reduction, emissions mitigation, and the prevention of hazardous waste disposal.

The Economic Advantage

Beyond environmental considerations, continuous pyrolysis plants offer a compelling economic case. This chapter examines the cost-effectiveness of continuous pyrolysis, considering factors such as operational efficiency, revenue streams, and profitability.

Applications Across Industries

The versatility of pyrolysis products opens doors to a multitude of applications across various industries. This chapter showcases how pyrolysis oil, carbon black, and syngas find utility in sectors ranging from energy production and manufacturing to agriculture and more. If you are interested in this macine, contact pyrolysis equipment manufacturers.

Addressing Challenges

While continuous pyrolysis holds immense promise, it is not without its challenges. This chapter addresses technical, regulatory, and market-related obstacles and discusses potential solutions to facilitate the widespread adoption of this technology.

Paving the Path to Sustainability

The integration of continuous pyrolysis plants into waste management and resource recovery is a crucial step toward achieving sustainability goals. This chapter highlights how these plants align with global sustainability initiatives and promote a circular economy.

Innovations and Future Prospects

As technology evolves, so do the possibilities of continuous pyrolysis. This chapter explores ongoing innovations in the field, from process enhancements to product diversification, and speculates on the future trends and potential advancements in continuous pyrolysis technology.

Conclusion: A Greener Tomorrow

In conclusion, continuous pyrolysis plants are catalysts for transformative change in waste management, resource recovery, and sustainable practices. They embody the ethos of environmental stewardship and economic viability, where waste is reimagined as a valuable resource, and the pursuit of sustainability guides us toward a cleaner, greener, and more prosperous future.