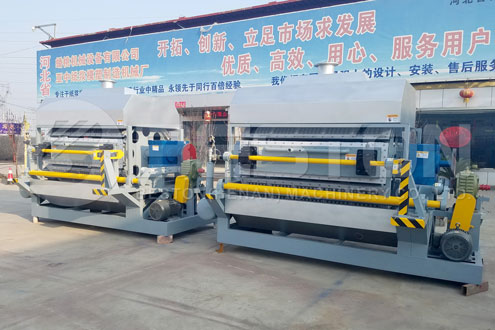

Egg tray making machines (Máquinas para hacer cartones de huevos) have transformed over the years. They have become more automated than ever before. Modern technology has allowed mechanisms to control virtually every aspect of the production of egg trays that are produced. Finding one is not that difficult part of this process. You need to know that the one you will purchase will create as many egg trays as you will need. Production is the key to keeping up with the eggs you are producing. Here are three easy steps that you can use to buy the best egg tray making machine at a good price.

Why Do Egg Tray Making Machines Matter?

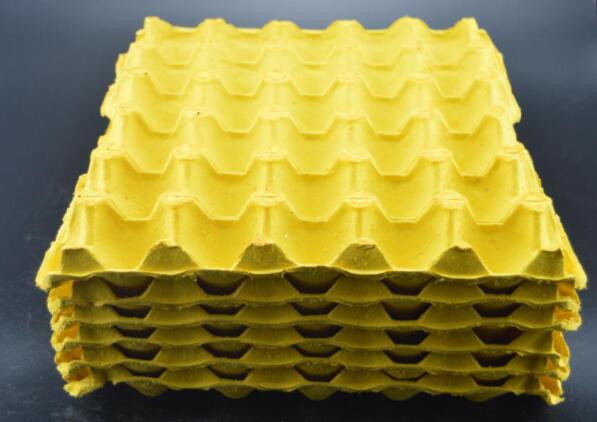

These machines are necessary for the production of egg trays which are what hold the eggs that you will produce. Without them, you would have no way of keeping them safe or delivering them to potential buyers. If you are producing thousands of eggs every day, having an automated system is absolutely necessary(maquina para hacer maples de huevos). That’s why it’s important to not only get one of the best units but also one that is affordable for your business. There are three specific steps that you must take to find the right one. This will only take a little extra time, but by following these suggestions, you will save money and get the best one.

Three Steps To Obtaining The Best Egg Tray Making Machine

The first step of the process is to find as many as possible. You will want to focus only on those that are automated if production is your primary focus. Second, you will then assess them based upon different parameters, making sure that they are top-of-the-line. Finally, you must consider the price of each of these. Some of them are going to be much more affordable than others. Based on all of this research, and interacting with the manufacturers, you will eventually find the best one for your company.

What Parameters Are You Looking For?

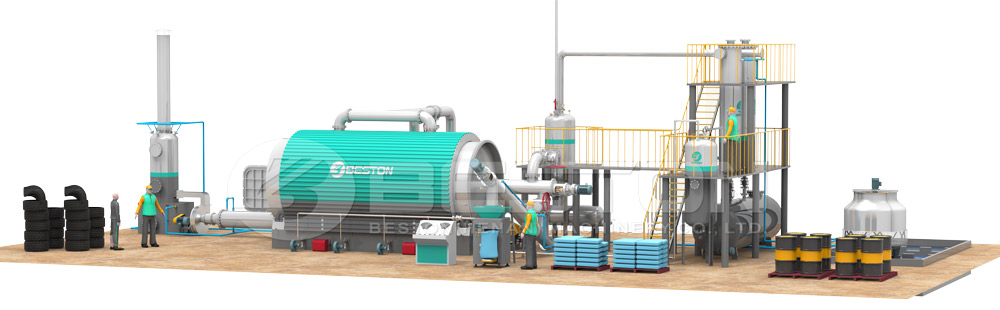

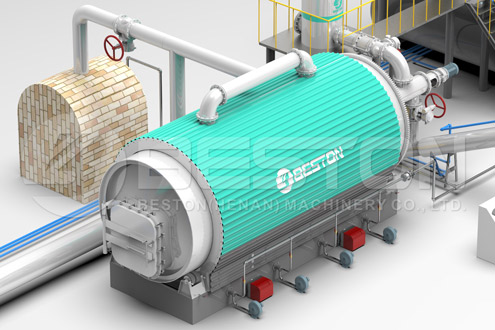

The parameters you are looking for will include how many pieces they can produce per hour. At a very basic level, a thousand egg trays can be made without you having to do very much work. Larger units can produce as many as 6000 per hour which might be exactly what you need because of the size of your business(Bestongroup). From there, you will then look at the forming mold quantity, the power consumption, labor force involved, and how much material will need to be used to create the egg trays you are making.

Although this is a lot of work, this will eventually lead you to a machine that will accommodate your business. You will have more than enough egg trays to store and sell the eggs that you are making on a regular basis. Many of these are going to be unaffordable, which is why you must keep searching(https://www.bestoneco.com/maquina-para-hacer-cubetas-de-huevos-en-chile/). By going overseas, you will eventually find one that is at the right price that has a high enough production value. All of this information should lead you to an egg tray making machine that is perfect for your business by using these three simple steps.