In the realm of culinary craftsmanship, the journey from raw biomass to the smoky allure of a perfectly grilled barbecue involves a fascinating intersection of tradition and modern technology. At the heart of this transformation lies the enigmatic charcoal machine, a technological marvel that has evolved to redefine the very essence of the grilling experience.

The Genesis of Charcoal Production

The process begins with the careful selection of biomass, often derived from sustainable sources such as hardwood, coconut shells, or fruit pits. This raw biomass, through the alchemical process of pyrolysis, is subjected to high temperatures in the absence of oxygen, birthing the elemental precursor to grilling magic: charcoal.

Pyrolysis: Nature’s Alchemy

Pyrolysis, a term often confined to scientific circles, describes the transformative thermal degradation of organic materials. This arcane process, occurring within the bowels of a charcoal machine, liberates volatile compounds and moisture, leaving behind a carbon-rich residue—the very essence of charcoal. The precise orchestration of temperature and residence time in the machine’s chambers ensures the optimal conversion of biomass into this culinary black gold.

Modern Marvels: The Charcoal Machine Unveiled

Retort Kilns and Rotary Furnaces

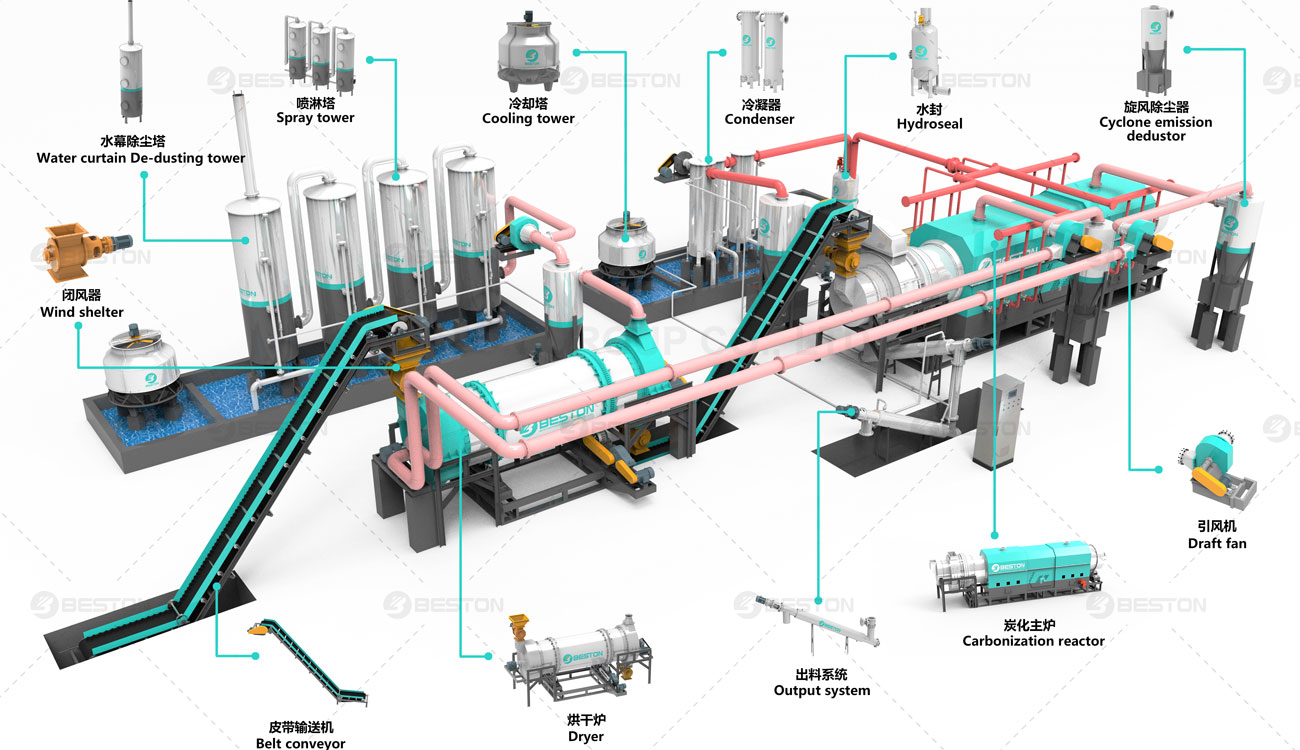

Enter the realm of modern charcoal production, where traditional earth mounds yield to the efficiency of retort kilns and rotary furnaces—a testament to the relentless pursuit of precision. The charcoal machine, in its contemporary form, employs these cutting-edge technologies to elevate the quality and consistency of charcoal production. The retort kiln’s controlled environment allows for maximal yield and minimizes unwanted by-products, while the rotary furnace’s mechanized precision ensures uniform carbonization.

Carbonization Chambers and Heat Recovery

Within the labyrinthine chambers of a wood/rice husk/straw/bamboo/sawdust/coconut shell charcoal making machine, carbonization unfolds with meticulous precision. The biomass undergoes a metamorphic journey, shedding its volatile components until what remains is an assemblage of carbon structures ready to impart their smoky flavor to grilled delights. To enhance efficiency, modern machines often incorporate heat recovery systems, reclaiming thermal energy expelled during the process to fuel subsequent cycles—an elegant dance of sustainability and technological ingenuity.

The Culinary Alchemy of Charcoal

The Flavor Spectrum

Charcoal, the culinary chameleon, possesses a diverse flavor spectrum derived from its botanical origins. Hardwoods impart a robust smokiness, while coconut shell-derived charcoal lends a subtly sweet undertone. The charcoal machine plays a pivotal role in shaping this flavor profile by controlling the carbonization process, allowing grill enthusiasts to curate a nuanced gastronomic experience.

Temperature Control and Culinary Mastery

Grilling, an art form in itself, relies on precise temperature control—a feat achieved through the selection of the right charcoal and the mastery of the charcoal machine. The modern griller, armed with a myriad of charcoal options, can manipulate the intensity and duration of heat, transforming each culinary endeavor into a symphony of sizzling perfection.

Sustainability and Innovation

Waste Utilization and Eco-Friendly Practices

Beyond the gastronomic realm, the coconut shell/rice husk/straw/bamboo/wood charcoal machine is increasingly viewed through the lens of sustainability. Innovative approaches include utilizing agricultural residues or invasive plant species as biomass feedstock, transforming waste into a valuable resource. This eco-friendly paradigm shift aligns with the ethos of responsible production and consumption, paving the way for a greener barbecue culture.

Carbon Sequestration and Beyond

In a surprising twist, charcoal production becomes a potential player in carbon sequestration efforts. The carbon-rich residues left behind by the charcoal machine can be incorporated into soil, enriching its composition and serving as a carbon sink—an unexpected synergy between culinary indulgence and environmental stewardship.

Conclusion: Where Tradition Meets Technology

As we savor the smoky essence of a perfectly grilled barbecue, it’s worth acknowledging the intricate dance between tradition and technology orchestrated by the charcoal machine. From the clandestine alchemy of pyrolysis to the modern marvels of retort kilns and heat recovery systems, this journey reflects the evolution of a timeless culinary companion. In the realm of biomass to BBQ, the charcoal machine stands as a silent artisan, shaping our culinary experiences and embracing the responsibility of sustainable gastronomy. For a closer look at our products/services, don’t hesitate to check out Beston Group.