Every tire recycling plant will have reports that are produced that will demonstrate its level of efficiency. A good tire pyrolysis project report can tell you how many rubber tires were produced, and also how much charcoal and biofuel was made. By monitoring these reports, you can get a better idea of how efficient they are. If you have noticed that the one you are using is not doing well, investing in another might be a good decision. If you are ready to obtain one of the newer pyrolysis plants on the market, this is how you can find a tyre recycling plant business plan quickly.

How Do Tire Recycling Plants Work?

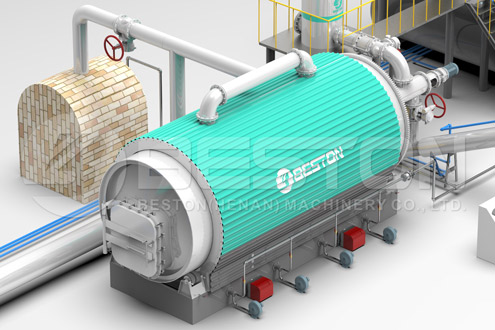

In the same way that any pyrolysis plant works, they are designed to convert organic material into charcoal. The high heat used in the reactors, and the removal of oxygen from within the chamber, is what allows the charcoal to be made. It can be a small unit, or you may have purchased a large pyrolysis plant. When you have access to millions of rubber tires, this can prove to be profitable, and it will also help the environment. Simply chip up the tires into smaller pieces, feed them into the reactor, and it will do the rest. Once done, you can generate reports that will show you how efficient they actually are. Contact this waste tyre recycling plant manufacturer.

Why The Tire Pyrolysis Project Report Matter

The reports matter for two reasons. One of those reasons has already been mentioned. It enables you to monitor the production level of the tire recycling plants. The other reason you need to read them is to see if there are any problems. Older models tend to have more than newer ones. It also allows you to determine what component on the recycling plant is not functioning so you can make improvements.

An Overview Of These Unique Plants

All of them begin with a conveyor belt system. This is where the chipped up pieces of tire will be sent. They will eventually arrive at the reactor where they will be placed inside. The chamber will be closed, and once the process starts, you can monitor every aspect from the computer console. This same information can be presented in a report that will also include unique statistics. For example, it can tell you about the hourly feeding capacity. It will also monitor the operating pressure. The total power consumption may also be on this report. This information is vital to maintaining your system. If you can get specs on the latest units, you can compare those with the production levels you have right now. Once the reaction is over, the charcoal will be harvested along with the bio oil and biofuel. This continuous pyrolysis equipment is also a good option.