Pyrolysis is a process that decomposes organic matter at high temperatures in the absence of oxygen. It can be used to produce biochar, charcoal, or renewable energy such as heat and electricity. In addition, pyrolysis is a green process that does not depend on fossil fuels for its production and therefore decreases greenhouse gas emissions by minimizing dependence on non-renewable resources such as coal or natural gas. Then customers can get the pyrolysis oil from pyrolysis machine. Furthermore, it also reduces landfill waste which would otherwise pollute the environment.

Pyrolysis is also an efficient method of recycling waste because it does not require expensive materials or complex manufacturing processes to produce the final product, making this technology cost-effective and beneficial for the environment. The only thing required for this process to work is heat and a supply of oxygen, paired by a pyrolysis machine, also referred to as pyrolyzer.

Pyrolyzers are becoming increasingly popular for waste-to-energy practices due to their efficiency and ability to handle any type of biomass feedstock. They are also widely used in the production of biofuel, oil, and gas recovery.

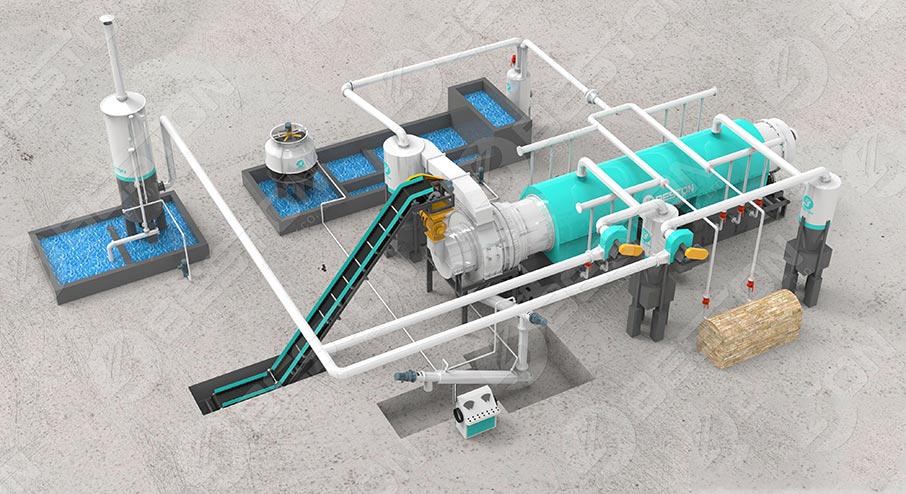

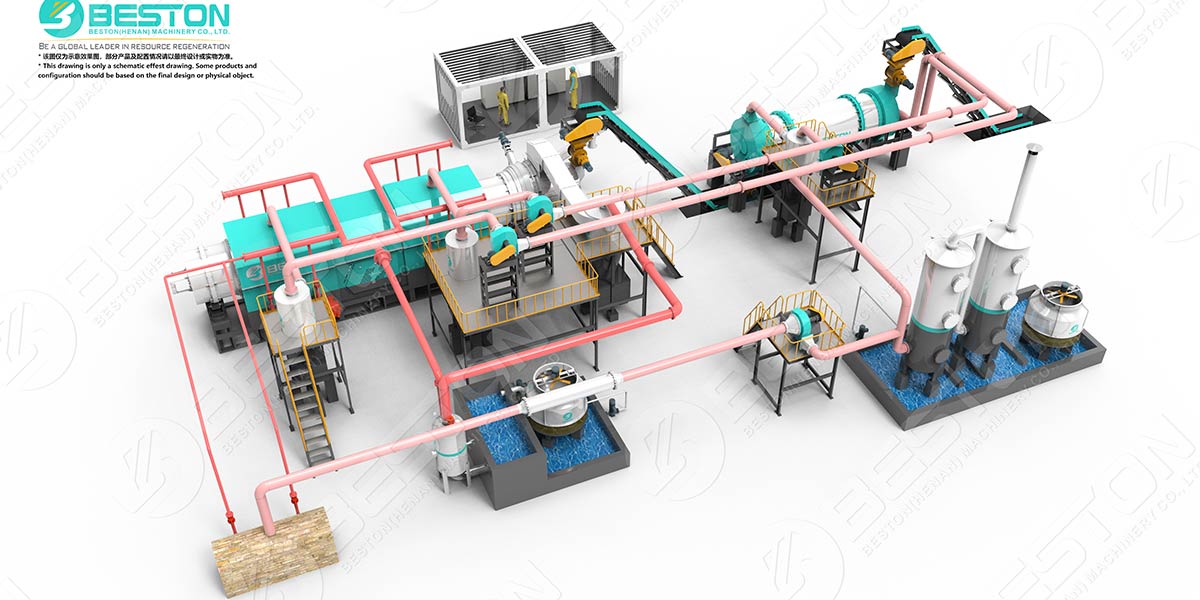

How Pyrolysis Machines Work

Oil sludge pyrolysis plant for sale work by heating biomass to temperatures between 400°C and 500°C, which is the temperature at which cellulose breaks down into oxygenated hydrocarbon gases. These gases are then cooled before they enter a separator that separates out the solid residue left over from pyrolysis called biochar or activated carbon. The gaseous mixture is then cooled before it enters a condenser, where the biochar and water are separated from each other.

Biochar can be used as fertilizer because it has been found to improve soil fertility while also increasing its carbon content by up to 60 percent! Biochar also increases agricultural productivity (up to 0.64 tons of crops per hectare, which is higher than the yield of crops grown in non-organic systems) and water storage capacity (up to eight times more water retention).

The gaseous mixture that results from pyrolysis can be used as an alternative energy source called syngas. The gas contains mainly carbon monoxide (CO), hydrogen, methane (CH), and carbon dioxide (CO). This gas mixture can be used to generate heat, electricity, or transportation fuels.

Uses of Pyrolysis Machine in Various Industries

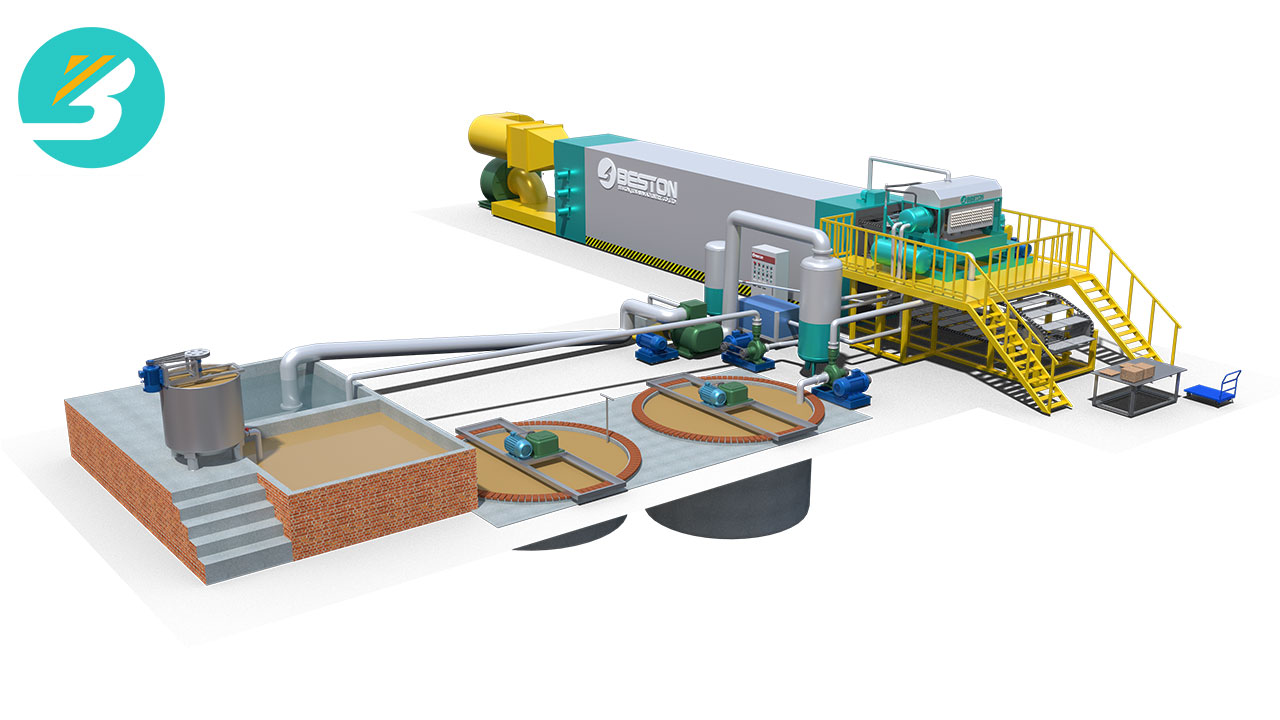

The paper industry is one of the most important users of pyrolysis technology because it recovers energy from wood residues or fast-growing trees that would otherwise be wasted. This process also produces a byproduct called black liquor, which is a valuable resource for the paper industry.

The production of plastic from petroleum is a very energy-intensive process, and pyrolysis offers a potential alternative to this industry. Pyrolysis can be used to convert waste plastic into fuel oil that can be used as an industrial fuel or even sold on the open market. There is a case for you to see – https://bestonmachinery.com/pyrolysis-plant/the-philippines/.

The agricultural industry is another important sector that can benefit from pyrolysis technology. Pyrolysis can be used to process agricultural waste products into biochar, which can then be used as a fertilizer or soil amendment.

Conclusion

Pyrolysis machine is a technology that can be used in a variety of industries to recycle waste products into useful and environmentally-friendly resources. The benefits of using pyrolyzers include reducing greenhouse gas emissions, improving soil fertility, and increasing agricultural productivity. With all of the benefits, a pyrolyzer is definitely considered an excellent investment for any business or industrial operation. See the details right now – https://bestonmachinery.com/tyre-to-oil-plant/.