Across the globe, rice is a staple food that is very common in the diet of a huge portion of the global population. But, when rice is harvested it leaves behind a lot of waste. After extraction of the edible rice, one of the major waste products of rice is rice husks. Previously, rice husks were disposed of to landfills as there was no other valuable use for them. However, the development of rice hull carbonizer technology has created new uses of rice husks. They can be used to produce biochar, a useful end product. Also, this eliminates the need for rice husk disposal hence saving on costs.

How a Rice Husk Carbonization Furnace Works

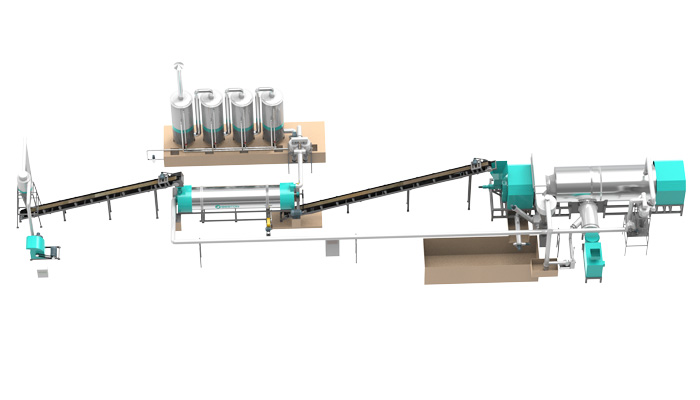

The major operating functions of a rice husk carbonization furnace for charcoal are feeding, carbonization, and discharging.

1. Feeding

Feeding usually involves delivering the risk husks into the furnace at a regulated pace. The feeding mechanism comprises a blower, husk preparatory area, and a husk holding bin. The preparatory bin is normally huge enough to hold a large volume of rice husk before it is transferred to the holding bin. The blower is placed below the holding bin and directs the husk forward to the carbonization chamber.

2. Carbonization

Carbonization is a process used to convert the rice husk into biochar. Normally, this process happens in the main segment of the furnace. Through combustion, carbonization generates stored energy from the rice husk. The carbonizing machine operations can be broadly classified into two categories; indirect burning and direct burning. After carbonization is complete, biochar and combustible volatile gases emerge as the end products.

3. Discharging

The blower is used to direct air into the combustion chamber from three points. The air helps to support carbonization and assists the discharge system to expel the carbonized husk and ash. It will drive out the ash to prevent the discharge orifice from clogging. The ash discharge mechanism is in the lower section of the furnace. After being blown away, the discharged ash is harnessed into an ash container or tank by a screw conveyor.

Rice Husk Carbonization Furnace Applications

Currently, the rice husk carbonization furnace designed by Beston Machinery China is used in some rice mills and rice drying centers. Previously, for businesses in the rice processing sector, risk husk was considered as the primary waste product. But now, they can process the rice husk and produce a useful energy source – biochar. They can generate their drying fuel and eliminate the challenges related to the proper disposal of rice husks. In a lot of rice drying centers, the rice husk replaces the drying fuel, which helps in reducing rice husk disposal costs and drying fuel expenses.

Wanna learn more details about the carbonization furnace, visit https://www.bestongroup.com/sawdust-charcoal-making-machine/.