If you are looking for an an affordable and safe way to take waste biomass out of the environment you need to invest in a waste pyrolysis plant. This plant takes a variety of waste materials and heats them up to a high temperature where they will be turned into charcoal. The charcoal is easy to use for a variety of different things and you can take it and sell it or use it for heating and cooking. This machine is a strong investment and you can make your money back with it fast. Read on to learn the top benefits of the waste pyrolysis plant.

Converts Biomass To Charcoal

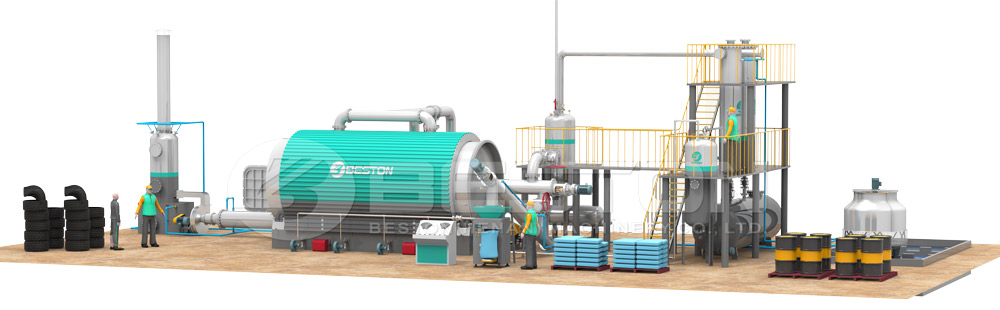

The waste pyrolysis plant takes a variety of types of biomass and turns them into charcoal. You can use coconut shells, rice husk and many other forms of biomass to produce charcoal. The biomass is free or cheap so you don’t have to spend a lot of money to run the machine. The machine takes many different types of biomass and turns it into charcoal so you won’t have any issues with producing the charcoal. The machine converts biomass fast and it turns it into safe and reliable charcoal that can be used for a variety of purposes. Get pyrolysis plant cost here.

Economical To Operate

The waste pyrolysis plant is economical to operate and it won’t cost you a lot of money in utility costs. The machine is designed to work continuously and to use as little energy as possible. This machine is good for the environment and it won’t produce much pollution which makes it very safe to operate. This machine is the perfect investment because you won’t have to spend a lot of money on utilities.

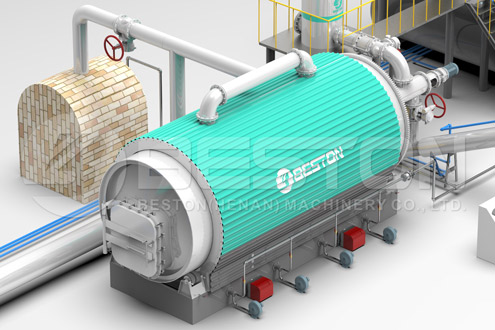

The machine heats up the biomass fast so it converts plenty of biomass to charcoal. The biomass is going to be heated up right to the optimum temperature and will be converted into charcoal. The machine works fast and the heating chamber is designed to heat up quickly so it reaches the optimal temperature faster. If you invest in the continuous machine you can run the machine continuously and you won’t have to keep stopping it to let it cool down. The continuous machine is a great investment and it will work hard for you. This tire recycling plant for sale makes it easy to get things done and it is just what you need when you want to get a lot of work done fast.

Produce High Quality Charcoal

This machine produces high quality charcoal that is easy to sell and use in a variety of ways. If you are looking for a charcoal machine that works fast and does everything it needs to do quickly then you can’t go wrong with this machine since it is so effective. The tyre to oil plant will work hard for you and provide with lots of quality charcoal. This machine can pay for itself quickly and it gives you all of the production capacity that you need to get things done.