Purchasing any type of industrial equipment can be an expensive decision. Most of them are going to be hundreds of thousands of dollars, sometimes millions, depending upon their size and capabilities. If you are investing in a waste pyrolysis plant, you will note right away how many different businesses sell them and the vast differences between the prices that they are offering them for. What you want to do is talk to as many companies as possible, get quotes from all of them, and then decide on the one that fits your company the best.

What Does A Pyrolysis Plant Typically Cost?

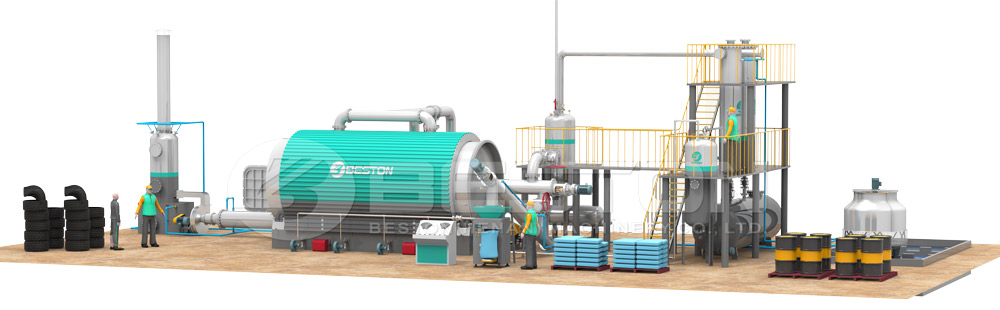

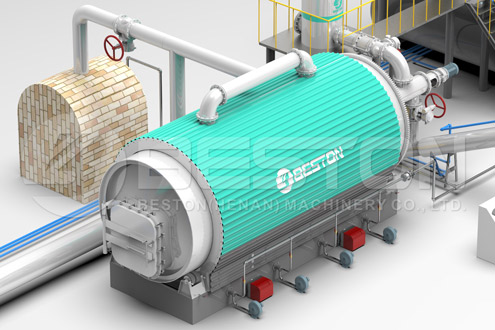

These can cost anywhere from a couple hundred thousand dollars for a smaller unit, to millions of dollars for a full-fledged pyrolysis plant. The only reason that you would want to invest in one of the larger units is simply because they are capable of processing all of the materials that you have at your disposal. Therefore, consider what you have access to, and how much you will have each day, before making your final decision. By doing so, you can cut your costs, and also find one of the best companies that is selling one for less.

Are They Easy To Use Or Set Up?

Another question that you will want supposed to these individuals is how easy it is to set up once it arrives. You may not understand how to put this together, if you’ve never had one before, so it’s good to have this information up front. Finally, you need to ask about the operations. You need to know how many hours it will take to get started, and how much of your time will be spent monitoring the entire operation. These questions are important, especially if you have limited numbers of people that work for you, or limited numbers of individuals that have never used one of these machines before. We also have mini pyrolysis machine for sale.

How To Save Money When You Make A Purchase

If you want to make your purchase, and you have decided on one over all of the others, make sure that it is at the lowest possible price. They may have other models from the same company that are just as applicable, but they are charging far less for them. By making these simple inquiries, you can save a lot of money, and position yourself to produce as much material as possible. More: https://www.bestongroup.com/.

Now that you know what is the average pyrolysis plant cost, you can start shopping today. You will find one, eventually, that will be within your price range that will have the highest amount of output possible. It may take several weeks to get your estimates returned to you, but over time, you will eventually find one that will make sense. If you do have access to large quantities of plastic, rubber, or any type of municipal solid waste that can be used, you should consider getting a larger one at an affordable price. Also inquire about pyrolysis plant costs related to shipping so that you are not shocked by the final price.