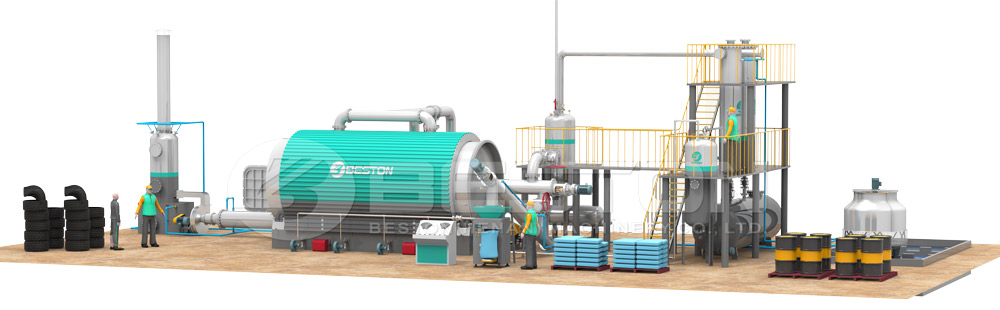

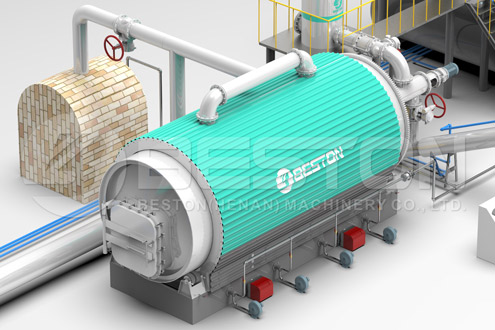

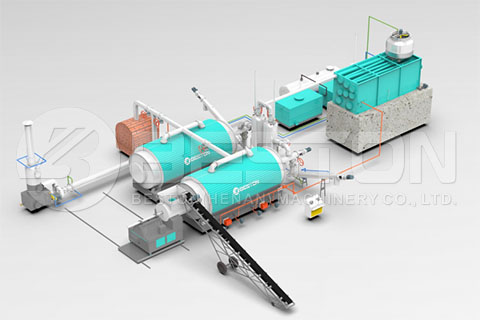

Are you looking for a high-quality tire pyrolysis plant for sale? If so, you have come to the right place. It might be hard to choose the best tire pyrolysis plant for sale, especially if you are a first-time buyer. There are hundreds of products out there, but all of these plants are not alike. Hence, you need to do your homework properly before investing in the best tire pyrolysis plant for sale. Selecting the wrong plant is a waste of your hard-earned money. Here are some of the most important factors to consider when choosing the best tire pyrolysis plant for sale.

Many buyers make the mistake of settling for the first tire pyrolysis plant they come across. This isn’t the best thing to do when choosing the best product. You should do the proper research and talk to several quality sellers before opting for the best product depending on your budget. Don’t forget to compare 3-4 tire pyrolysis plants on the market before settling for the best product for your business. Click here to know more: https://bestonpyrolysisplant.com/.

If you are a new buyer, and this is your first time shopping for a tire pyrolysis plant for sale, you may not know where to start. When you don’t know about the best manufacturers in the industry, it can be difficult to choose the right product. That’s where a personal referral from a trusted source can come in handy. If you have a friend who knows someone in the industry, you can get a referral from them. They are the best people to recommend the right manufacturer or supplier to you. That way you are sure of investing in a high-quality product at an affordable price.

The internet is a great place to start your search when shopping for a quality tire pyrolysis plant on the market. You should always find a reliable seller that provides high-quality tire pyrolysis plants. There are numerous online review sites for this purpose. Don’t forget to choose independent online review sites to check what other customers are talking about the tire pyrolysis plants out there. These are important things to consider when shopping for the best tire pyrolysis plant for sale.

Are you shopping for the best tire pyrolysis plant for sale? If so, there are many things to consider before investing in the best product for your business. The reputation and experience of the manufacturer or supplier are important things to consider. The aforementioned article provides information on some of the most important factors to consider when choosing the best tire pyrolysis plant for sale. More information on Pinterest: https://www.pinterest.com/bestonchina/pyrolysis-plant-for-sale/.