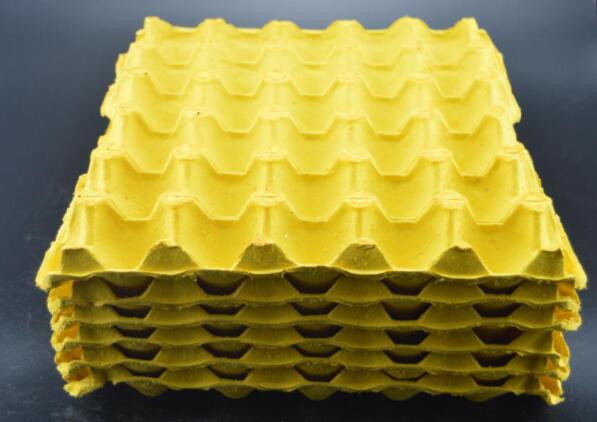

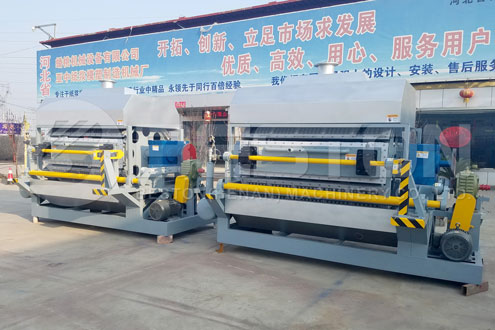

If you are planning to buy a molding machine, you must be thinking about its features. Most buyers are aware of the importance of investing in the right molding machine as they know its significance in the overall production process. The overall quality of product delivered by a pulp molding machine depends, to a large extent, on the quality of the machine itself. This is why, you need to pay special attention to the features described below in order to get the best value for your money when you’re buying a pulp molding machine.

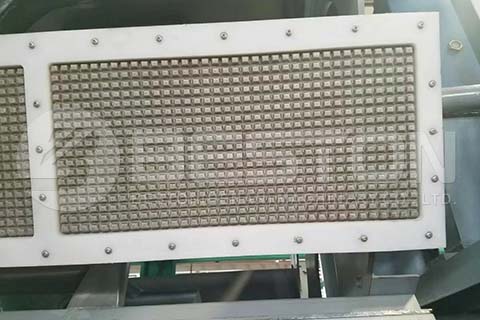

One of the major components of a molding machine is the pulper. It is the component that is responsible for turning wastepaper into the pulp which is then molded into various products. It looks like a giant circular tank. In this tank, all the raw materials and water are mixed together with the help of an agitator. The agitator moves all the raw materials at high speed to create a consistent mixture that looks like thick porridge. The most important factor that affects the quality of end product is the consistency of this mix of raw materials and water created in this part of the machine. Click here to know more: https://eggtraymakingmachine.net/apple-tray-making-machine/.

If the end product is inconsistent, the trays or other products are not going to be of good quality. There will be other problems and it is likely that the whole batch will be rejected by the buyers. Hopefully, you have, by now, understood the importance of quality of the pulper. To a large extent, the quality of pulp prepared in this tank depends on the speed and power of this component. Therefore, you should pay special attention to the speed and power of pulper when you’re comparing this component across various models.

Another important thing you need to keep in mind is that different products require different consistency. Sometimes, thicker consistency is required for a particular type of product but thinner consistency is needed for another type of product. A consistency controller helps in achieving the desired consistency.

To conclude, a pulp molding machine consists of a number of components and all those components need to produce consistent pulp to deliver a high-quality end product. This is why, it is important to compare the performance and quality of these components in order to choose the right molding machine. The above-mentioned tips should help you with your choice. Visit the site: https://eggtraymakingmachine.net/egg-carton-making-machine/.