The amount of waste tyres in the world has been increasing for decades. There are more people today than ever before in history. Just 50 years ago, to imagine that we would have landfills filled with millions of tyres would be unimaginable. However, this is becoming commonplace in every country, on every continent, because people are driving cars, flying planes, and writing more bicycles. In particular, the rubber tyres that are on automobiles are among the most prolific. These are often changed out every year. At that pace, without doing something about them, they could begin to fill landfills at an exponential rate that would simply become unsustainable. That’s why a tyre pyrolysis plant would be the best choice for companies that are responsible for collecting them. If you would like to invest in a waste tyre pyrolysis plant, these are the financial reasons why this might be a very good idea.

Why Would You Want To Invest In One Of These?

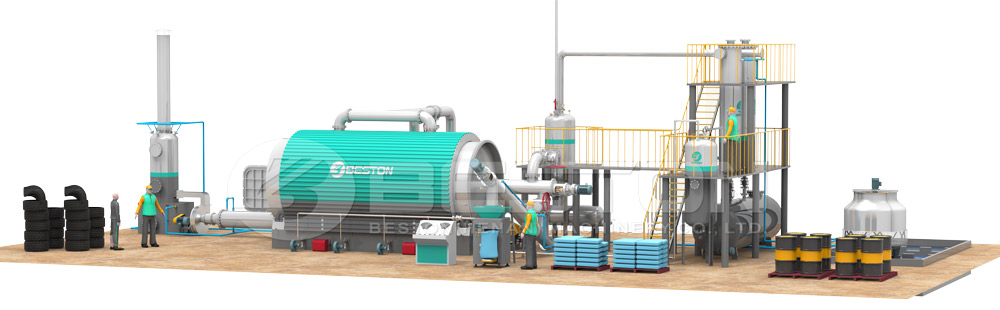

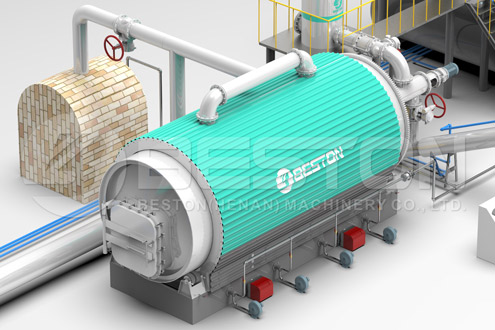

You should consider investing in one of these if you are in charge of a municipal solid waste plant. For example, you may receive hundreds of tyres every day, all of which will have to go to a landfill, unless you can recycle them right on the planet. A small pyrolysis machine or plant is going to break down the tyres. This will allow them to revert back to their elemental structure. This includes the production of charcoal, bio oil, and fuel that can be used with many vehicles, in particular diesel engines that burn this type of fuel. This fuel could be sold to the people that need it the most. Charcoal is always in demand. If you have a large supply of rubber tyres, or if you are constantly getting them, this would be a very wise investment.

If you do have access to millions of tyres, you will certainly want to get the largest one available. This will enable you to produce the most fuel from them. Not all of them are going to be the same size, or even have the same amount of output, but one of them is going to be in your price range that can handle all of the tyres. If you receive them daily, you could process them daily. They are designed to work almost 24 hours a day. You will need to clean them to get the fuel out of the pyrolysis reactor, but other than that, this business can be profitable and streamlined.

How To Find A Company That Can Send You One

Your ability to find one of these companies should be relatively simple. There are businesses worldwide that produce them every day. Some of these are quite large and can handle a large capacity of rubber tyres. Your job is to break them down into smaller components, put them into the pyrolysis oil plant, and then allow it to do its work. If you can, find vendors or buyers that will be interested in getting the biofuel or charcoal that you are going to produce. This can bring in a lot of money for your company by simply producing all of that fuel from the rubber tyres that you have accessible to you.

If you would like to invest in one of these rubber tyre pyrolysis plants, start looking for them today. It will be a fantastic investment for your company, allowing you to increase your bottom line substantially, using these products that would simply go to waste. If you have never done this before, it’s not that hard to figure out. They are very simple to use. Whether you get a large one, or a smaller unit, you can always be profitable with a waste tyre pyrolysis plant at your disposal. More information on the continuous tyre pyrolysis plant here.