The shift towards sustainable agriculture is crucial in addressing environmental challenges and food security. Among the various strategies to promote sustainability, the use of a rice husk carbonizer stands out as an innovative solution. This technology not only optimizes the utilization of agricultural waste but also contributes to soil enhancement and carbon sequestration, making it an essential tool for modern farming practices.

The Problem of Rice Husk Waste

Rice production generates significant amounts of waste, primarily in the form of rice husks. Typically discarded or burned, these husks contribute to environmental degradation when improperly managed. Open burning releases greenhouse gases and particulate matter into the atmosphere, exacerbating air quality issues. The challenge lies in finding effective methods to repurpose this abundant biomass into valuable resources while minimizing its ecological impact.

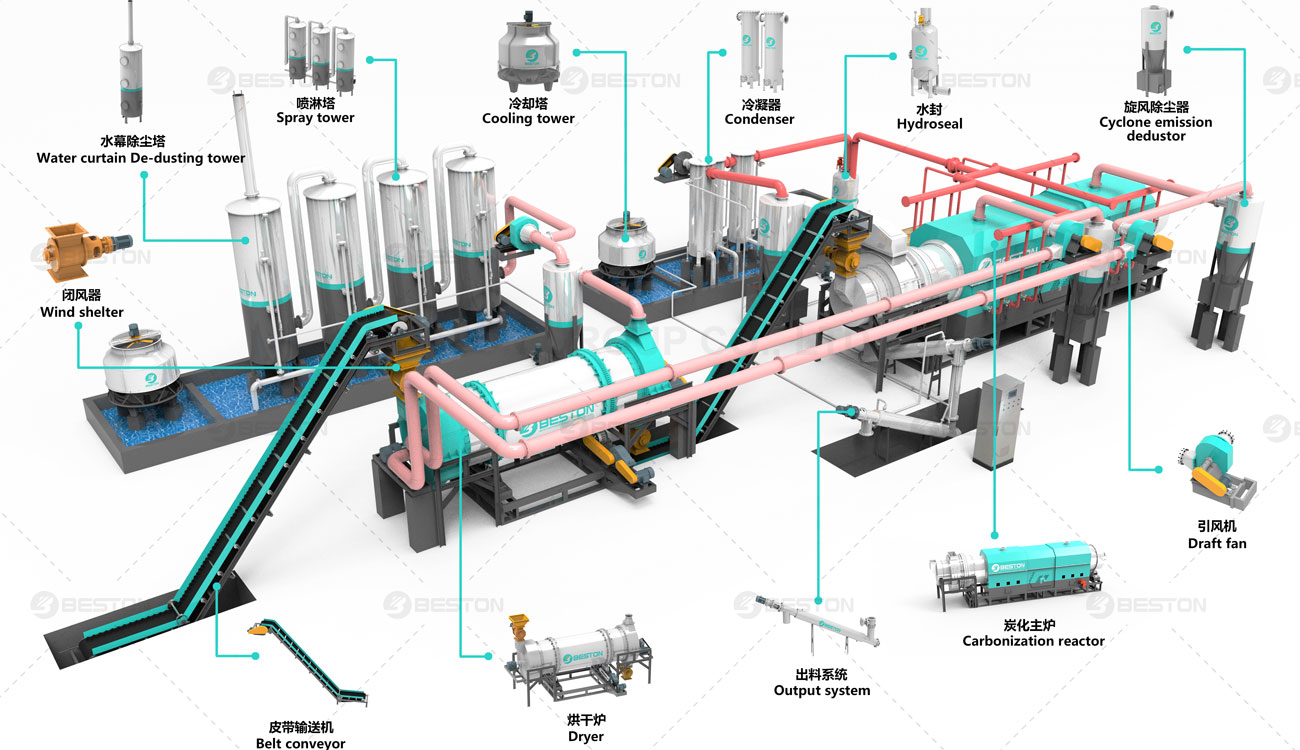

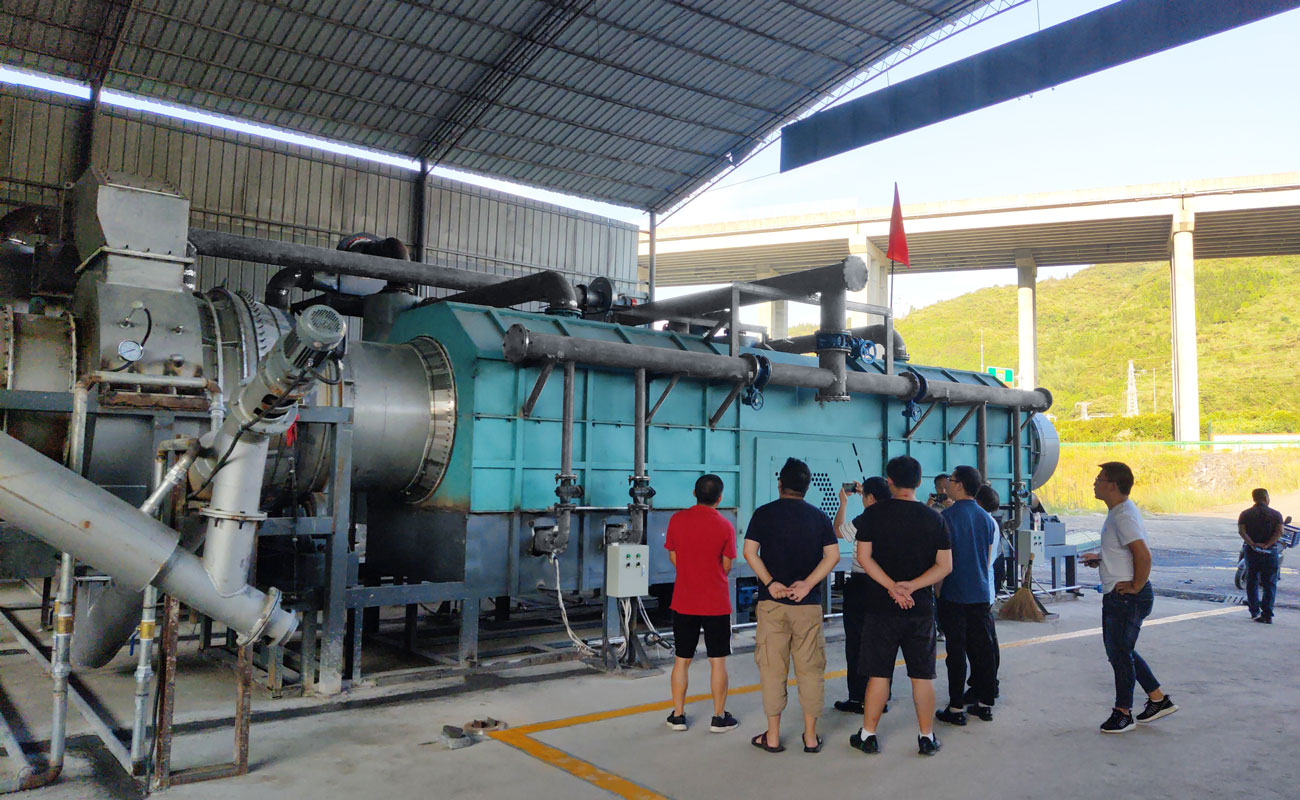

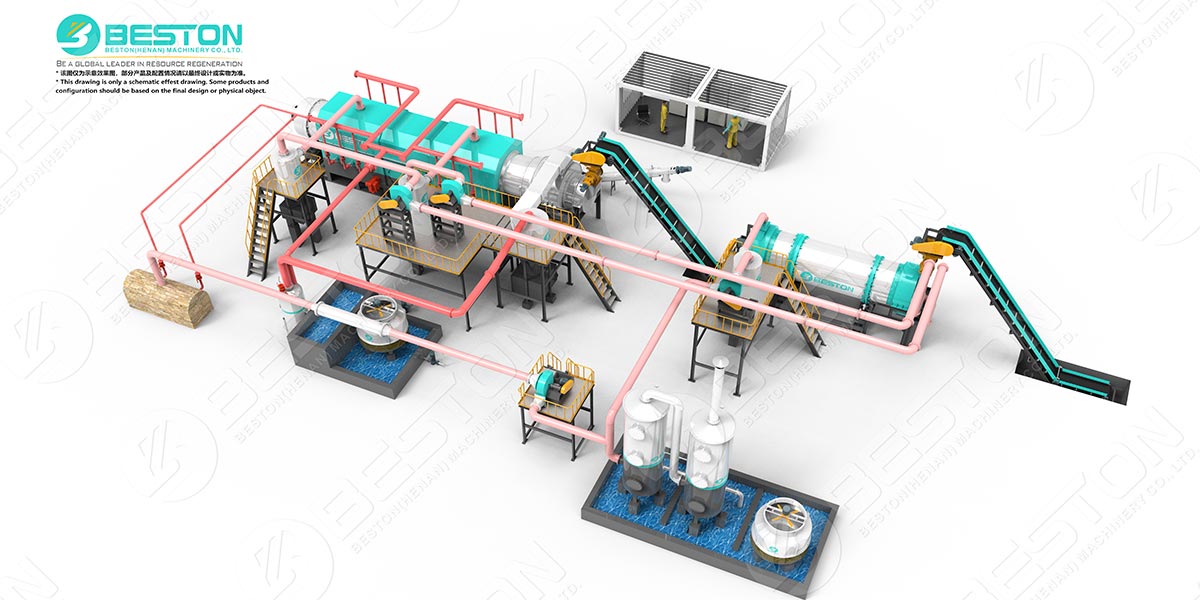

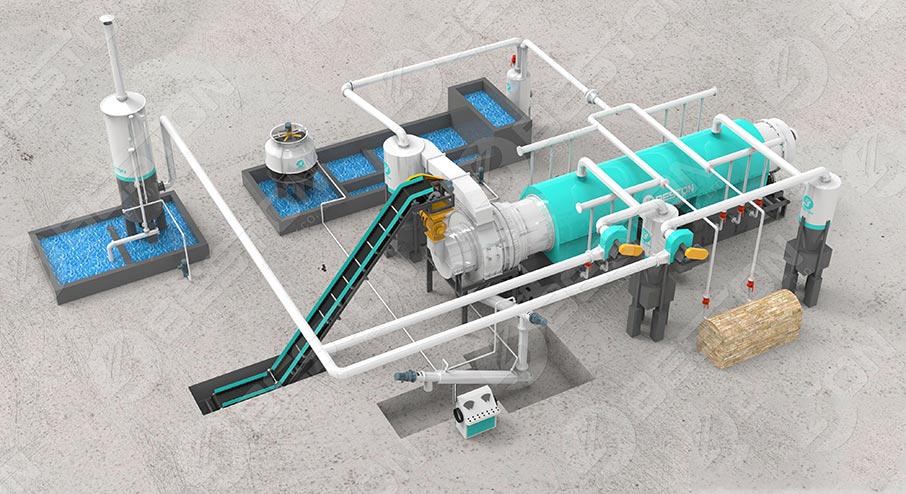

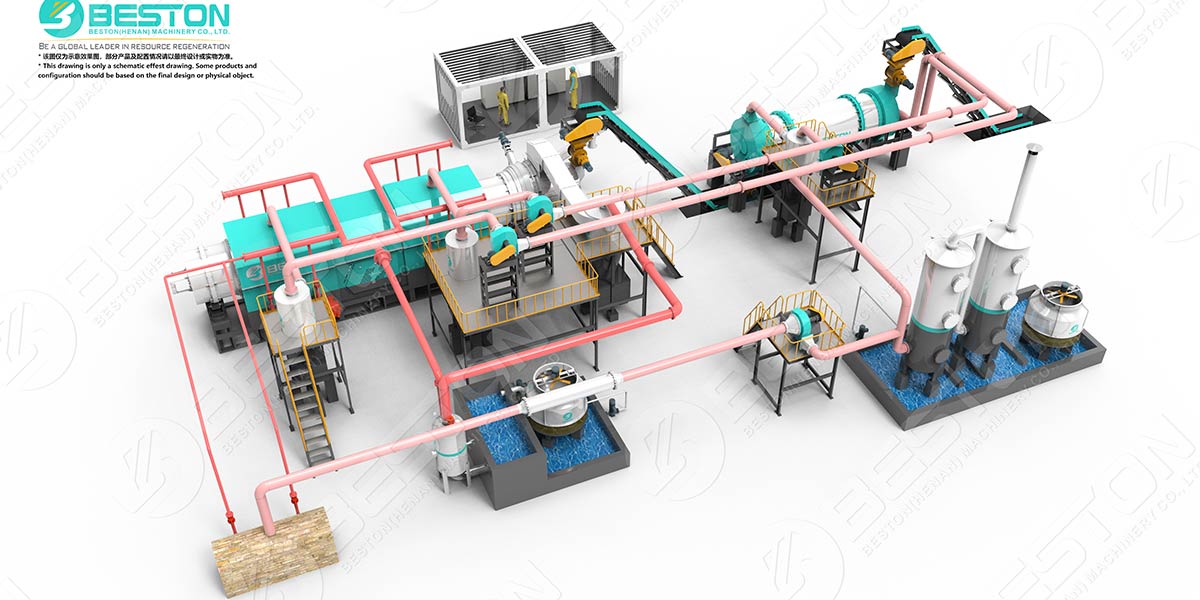

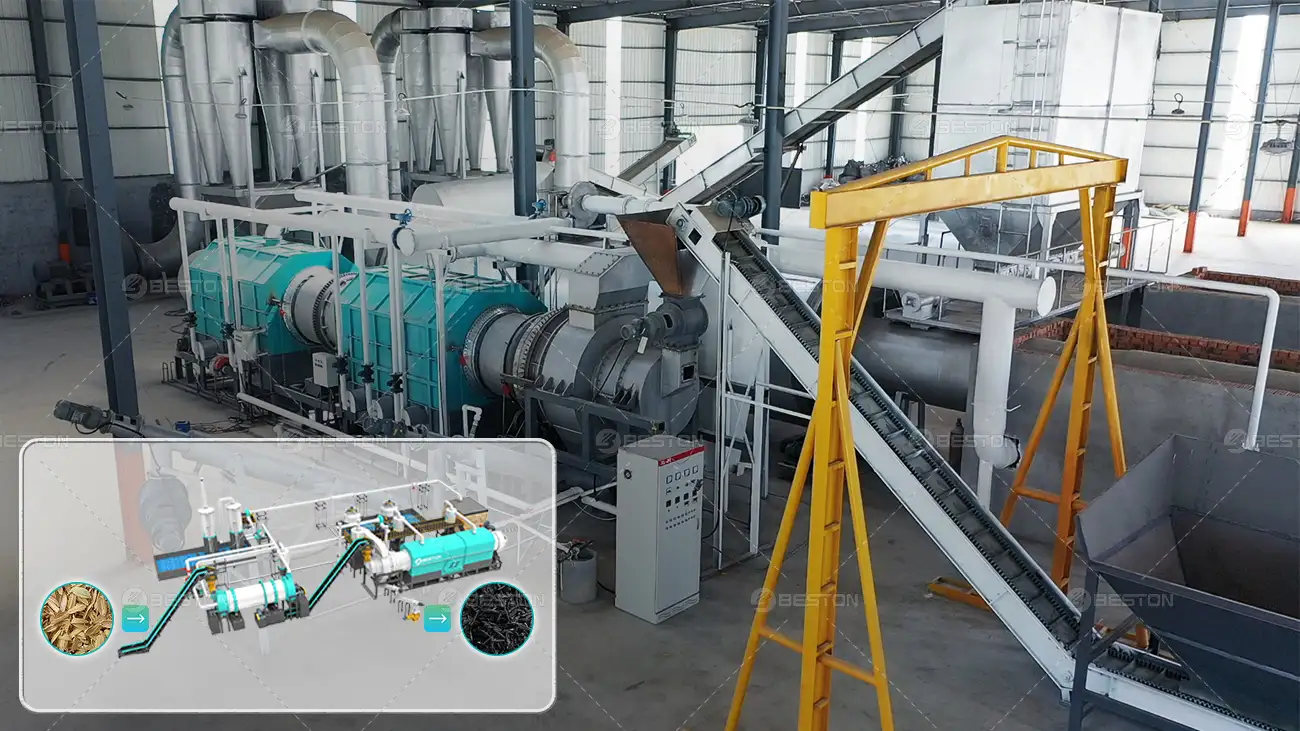

Mechanism of the Rice Husk Carbonizer

A rice husk carbonizer converts waste into biochar through a process known as pyrolysis. This thermal decomposition occurs in the absence of oxygen, allowing the rice husks to break down into solid carbon-rich material. The process also generates syngas and bio-oil, which can be harnessed as renewable energy sources.

The rice husk carbonizer operates efficiently, maintaining high temperatures and optimizing residence time to ensure maximum carbonization. Advanced models feature automated controls and emissions management systems, further enhancing their sustainability profile. This technology transforms an agricultural byproduct into a multi-functional resource that can support various aspects of sustainable agriculture.

Enhancing Soil Health with Biochar

One of the most significant benefits of utilizing a rice husk biochar pyrolysis equipment is the production of biochar. When applied to agricultural fields, biochar enhances soil properties, contributing to improved fertility and productivity. Its porous structure allows for increased water retention, reducing the need for irrigation and helping crops withstand drought conditions.

Biochar also improves nutrient availability by providing a habitat for beneficial microorganisms. These microorganisms enhance soil health, leading to increased organic matter content and improved nutrient cycling. As a result, farmers can achieve higher yields while utilizing fewer chemical fertilizers, promoting a more sustainable approach to crop production.

Carbon Sequestration and Environmental Benefits

The carbonization process inherently sequesters carbon that would otherwise be released into the atmosphere through decomposition or burning. When biochar is incorporated into the soil, it can remain stable for hundreds to thousands of years, effectively locking away carbon and mitigating climate change impacts.

By using a rice husk charcoal briquetting machine, farmers not only manage waste efficiently but also contribute to carbon footprint reduction. This aligns with global efforts to combat climate change and promotes sustainable land management practices. Furthermore, the reduction of agricultural waste through carbonization diminishes the risk of pollution and enhances local air quality.

Economic Viability and Value Addition

Integrating a rice husk carbonizer into agricultural practices offers economic benefits alongside environmental ones. Farmers can generate additional revenue streams by selling biochar, which is gaining popularity in gardening, landscaping, and soil remediation sectors. The rising demand for sustainable agricultural inputs enhances the market potential for biochar production.

Moreover, utilizing a rice husk carbonizer can decrease costs associated with waste disposal and fertilizer purchase. By recycling agricultural waste, farmers create a circular economy that minimizes waste and optimizes resource use. This approach fosters economic resilience, especially for smallholder farmers facing financial constraints. For more agricultural waste recycling solutions, please consult: https://bestonmachinery.com/

Challenges and Considerations

Despite the numerous advantages, the adoption of rice husk carbonizers may face challenges. Initial investment costs for equipment can be significant, particularly for small-scale farmers. Access to technology, training, and support services is essential to ensure successful implementation. Collaboration between governments, NGOs, and the agricultural sector can facilitate access to financing and technical assistance, promoting wider adoption of carbonization practices.

Furthermore, establishing local markets for biochar and educating farmers about its benefits are crucial for long-term sustainability. Engaging in awareness campaigns can empower farmers to make informed decisions about integrating carbonization into their agricultural systems.