There are different options when it comes to fuel, and one that is commonly used is charcoal. It is important to have quality charcoal, and all this can be possible when you have the right machine. The coconut shell charcoal making machine has become a popular option for many people because it has a lot of benefits. Investing in such a machine is going to prove to be a good thing because you are going to make a good return. There are many factors that are going to be at play, but having the right machine is going to be the first step.

It is important to choose a high-quality machine, which you can easily find in the market. You have to choose a reliable supplier for your machine because it is going to give you peace of mind. You should take your time to make the right choice because the last thing you want is regret when it is too late. With the many options in the market, it pays to research.

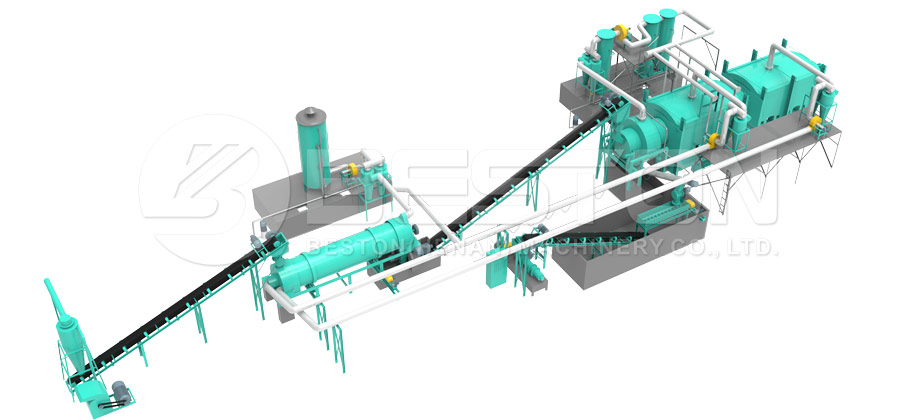

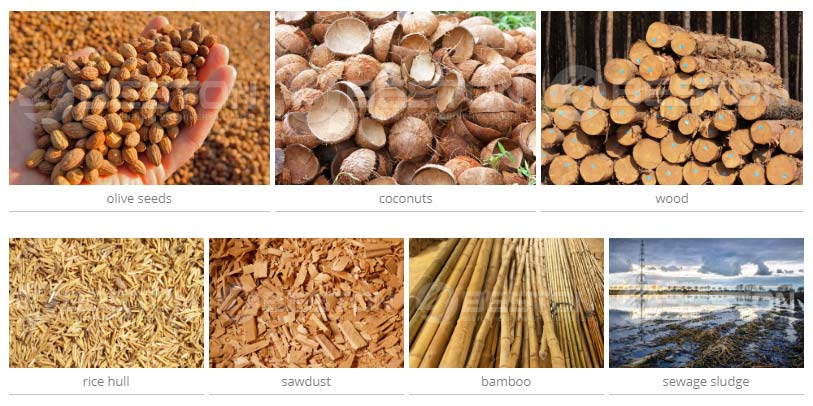

The coconut shell-charcoal making machine uses high temperature to convert charcoal shells into biogas and charcoal. The process uses an oxygen-free carbonization technology to do this. There are machines that have the ability to process coconut shells together with other waste components such as sewage sludge, sawdust, palm kernel shell, rice husk, agriculture, wood, bamboo, green waste, peanut shells, and municipal solid waste. There is a demand for coconut charcoal in the market, which makes this a good investment. Click here to know more: https://bestonpyrolysisplant.com/.

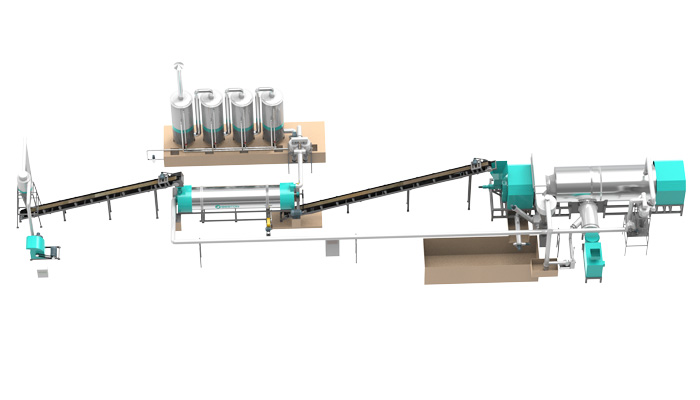

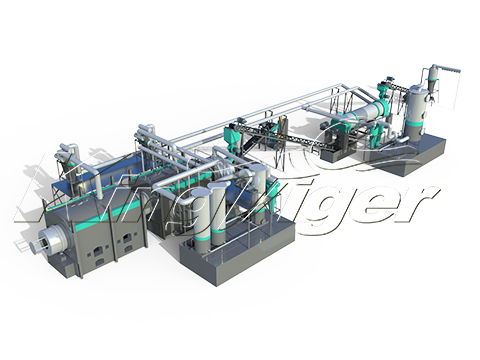

This machine comes in two types, continuous coconut shell charcoal, and bath coconut shell charcoal making system. The charcoal is going to be discharged after it has cooled. Another batch begins once the charcoal has been fully discharged. The continuous charcoal manufacturing plant is going to make charcoal on a continuous basis.

You should choose an automatic machine because it reduces the amount of work you have to do. All you have to do is wait for the output. There are different options to choose from. Research about the different options then choose one that works best for your business. Talk to the seller and ask any questions because it will help you choose a good charcoal making machine that is going to serve you well.

There are many benefits you can expect to get when you invest in a coconut shell charcoal making machine. There are many options to choose from out there. Look at your budget and choose a machine that will be able to provide the desired output.

Don’t make the mistake of just choosing any coconut charcoal making machine, take your time and understand the different options. Choose the right seller when buying a coconut shell charcoal making machine. See the website: https://bestonpyrolysisplant.com/rice-hull-carbonizer/.