The growing focus on waste management, energy recovery, and sustainability has driven significant interest in plastic pyrolysis technologies. These systems, which convert plastic waste into valuable products like bio-oil, carbon black, and syngas, have become essential tools in the circular economy. However, when investing in a plastic pyrolysis machine in Europe, understanding the cost structure is critical. This analysis explores various cost components involved in setting up and operating a pyrolysis machine in the European market, considering factors such as equipment, installation, operational, and regulatory costs.

Initial Investment and Equipment Cost

The upfront cost of acquiring a plastic to fuel machine is often the most significant financial commitment in the entire process. Prices for pyrolysis machines can vary widely depending on factors such as machine capacity, technology, and the level of automation.

-

Machine Capacity: Larger machines with higher throughput capacities will generally come at a higher price point. European pyrolysis plants tend to be designed for medium to large-scale operations, with capacities ranging from 5 to 20 tons of plastic waste per day.

-

Technology and Features: Advanced pyrolysis machines that feature automation, enhanced control systems, and higher efficiency come at a premium. Features like energy recovery systems (e.g., using syngas to power the reactor) or integrated gas cleaning systems can increase the overall cost. European manufacturers often offer state-of-the-art systems that incorporate these features, resulting in higher initial investment costs.

-

Brand and Manufacturer: The reputation of the manufacturer and the quality of the machine can also impact costs. Established European manufacturers with a proven track record for reliable and efficient systems will generally offer higher-quality equipment, though they may also come with a higher price tag.

Installation and Setup Costs

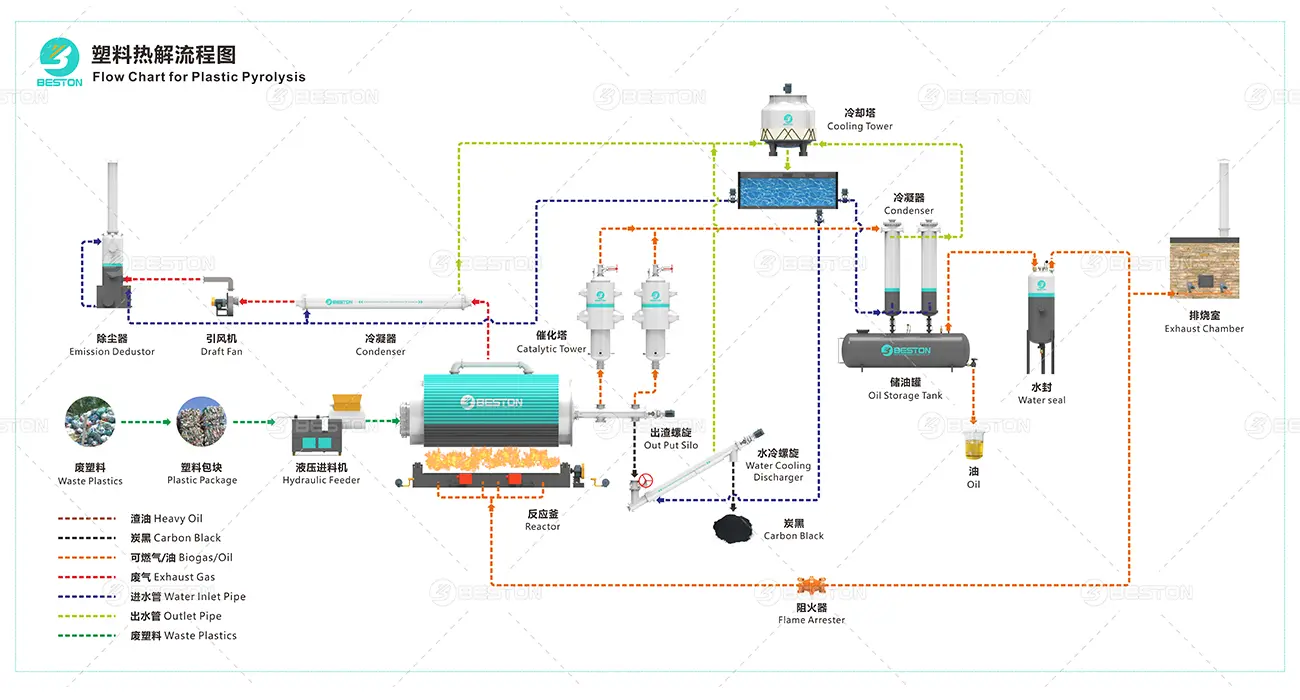

In addition to the machine itself, setting up a plastic pyrolysis plant in Europe requires significant infrastructure. These costs include site preparation, the installation of the reactor, and the integration of other systems such as the fuel recovery and gas collection systems.

-

Site Preparation: Depending on the location, the site for the pyrolysis plant may require various modifications. This includes foundations, access roads, waste handling facilities, and sometimes environmental protection measures to comply with local regulations. Site preparation costs can add an additional 10%–20% to the overall setup cost.

-

Installation: The complexity of installing the pyrolysis machine and other ancillary equipment (such as condensers, gas scrubbing systems, and fuel tanks) contributes to installation costs. This process often involves significant labor and technical expertise, especially when installing automated systems that require calibration.

-

Infrastructure Integration: For large-scale operations, the integration of the pyrolysis machine with other processes such as power generation, fuel storage, and waste management systems will also contribute to the setup costs. These systems may require the addition of specialized infrastructure to facilitate smooth operation, further increasing the initial outlay.

Operational and Maintenance Costs

Once the plastic pyrolysis machine is up and running, ongoing operational and maintenance expenses of pyrolysis reactor cost must be accounted for. These costs are crucial for understanding the long-term viability of the investment.

-

Feedstock and Waste Collection: The cost of procuring plastic waste, including logistics, collection, and transportation, is an important operational consideration. Waste plastic can either be sourced locally or imported, which influences the overall cost structure. In Europe, plastic waste costs are generally stable, but fluctuating prices based on regional supply and demand can affect costs.

-

Energy Consumption: Pyrolysis processes require substantial energy, primarily to heat the reactor. While some pyrolysis plants are designed to be self-sustaining by utilizing the syngas produced in the process, energy consumption remains a key factor. In Europe, where energy costs are relatively high, operating expenses can be significant. However, energy recovery systems that recycle heat and gases can reduce these costs over time.

-

Labor: Labor costs in Europe can be substantial, especially when managing highly automated systems. While advanced systems reduce the need for manual intervention, operators still need to monitor and control the system, handle logistics, and perform safety checks.

-

Maintenance: Regular maintenance is essential to keep the pyrolysis machine running at peak efficiency. Maintenance costs include replacing worn-out parts, cleaning systems, and periodic inspections. Advanced technology may reduce the frequency of repairs, but it may also come with higher costs for spare parts and technical support.

Regulatory and Environmental Compliance Costs

In Europe, environmental regulations play a significant role in determining the operational costs of pyrolysis plants. Stricter emissions standards and waste management regulations necessitate investments in equipment and compliance systems.

-

Environmental Permitting: Before operating a pyrolysis machine, companies must obtain permits from local or national authorities. This process involves regulatory compliance with air, water, and waste management standards, which can require substantial fees. Obtaining permits for the construction and operation of pyrolysis plants in Europe can be expensive.

-

Emission Control Systems: Pyrolysis plants produce various emissions, including particulate matter, volatile organic compounds (VOCs), and greenhouse gases. To meet stringent European environmental regulations, operators must invest in advanced emission control systems. These may include gas scrubbers, filtration units, and systems designed to reduce CO2 and other harmful emissions.

-

Sustainability Incentives and Grants: On the positive side, some European countries offer subsidies or incentives for sustainable energy projects and waste-to-energy initiatives. These programs can offset a portion of the investment costs, making the pyrolysis project more financially feasible in the long run.

Return on Investment (ROI) and Profitability

Ultimately, the cost of the pyrolysis machine must be weighed against its potential for profit. The market price of by-products such as bio-oil, carbon black, and syngas will determine the ROI of the investment. With the increasing demand for renewable energy and sustainable materials, pyrolysis systems in Europe offer significant profit potential. However, the balance between initial investment, ongoing costs, and market conditions must be carefully assessed to ensure a positive return.