As you harvest rice every year, you may wonder what else you can do with the rice husks that remain. This tedious process of stripping the husk from the outside of each grain of rice is a process usually handled by machines. Once it is done, you will have tons of material left over. This is typically placed back in the soil to replenish the nutrients which have been extracted by the plants. However, there is another alternative which includes purchasing a rice husk charcoal making machine that will convert this into a burnable fuel. This type of investment can be advantageous for businesses of all sizes.

How Does It Convert Rice Husks Into Fuel?

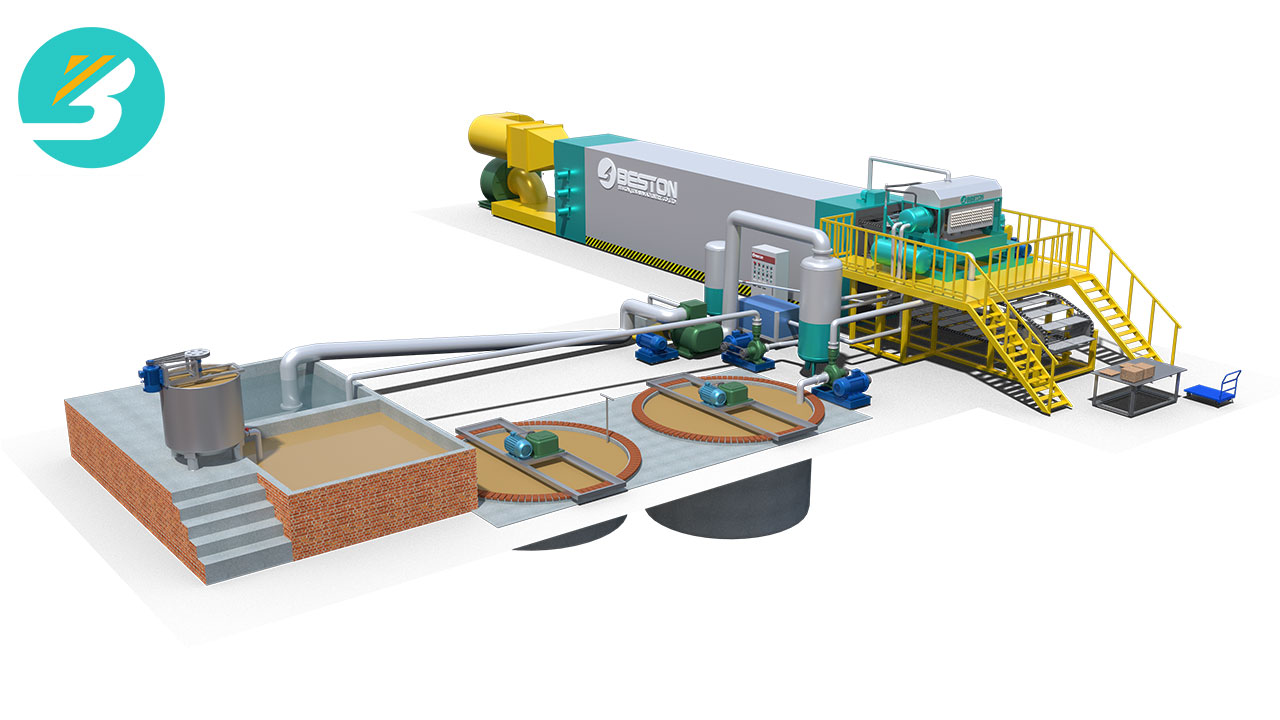

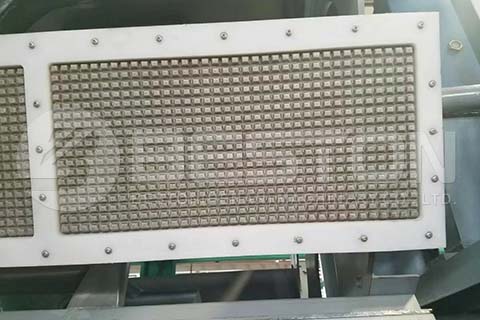

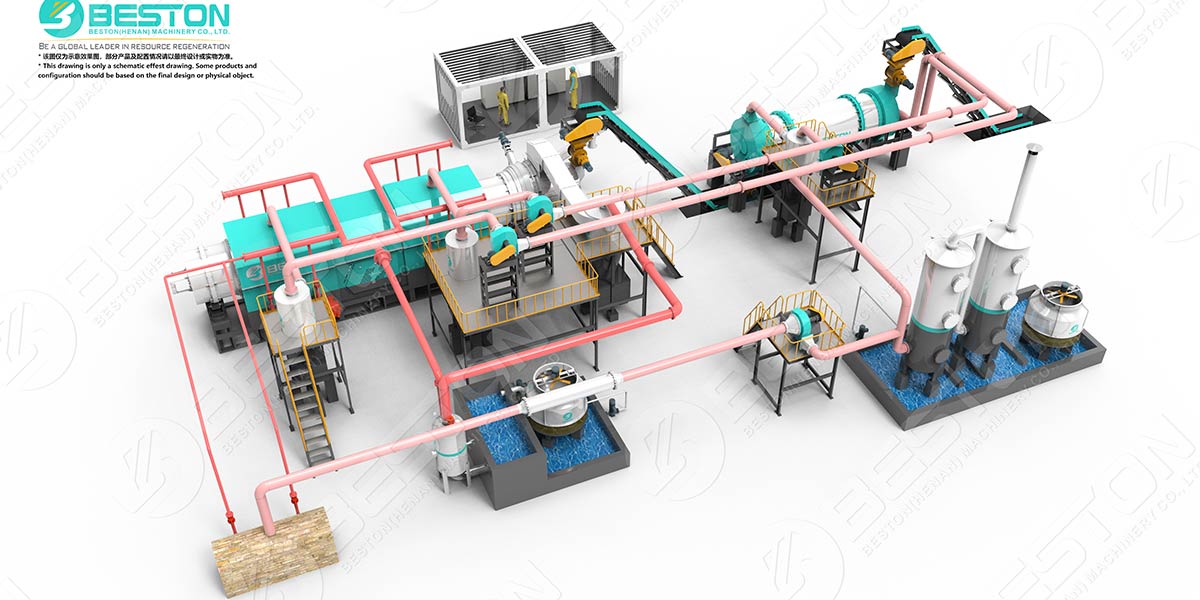

The primary process begins with are placing all of the rice husks into a reactor. This is a chamber where the materials can be placed and they will be sealed off from the outside. Within the chamber, heat will be administered, and oxygen will be removed which will prevent material from combusting. Once the process is completed, you will have burnable liquid and solid fuel that you can use or sell. Now that you know how this process works, you will now want to find businesses that produce them.

How To Find The Businesses That Make Them

The companies that manufacture rice husk charcoal machine are numerous. This is an industry that has been growing in recent years. As the population continues to expand, and people need more access to food, it is likely that rice fields are going to also get larger. This abundance of rice husks will lead to more companies making investments into charcoal making machines of all different sizes. You can find the companies that produce them by searching for charcoal making machines or pyrolysis plants that can produce these materials.

How Expensive Are These Machines?

If you are getting a charcoal making machine, it will likely be smaller in size. The overall output is going to be somewhat minimal. Unless you are investing into an entire coconut shell charcoal machinery, you will likely only produce enough charcoal and burnable fuel for your business. On the other hand, if you make a much larger investment into a pyrolysis plant, try to have enough material to use on a daily basis. Eventually, you will come across a business that you can trust that is producing rice husk charcoal production machines. This is a process that will help your business become more efficient and productive regardless of how much rice you harvest on an annual basis.

If you have not obtained a rice husk charcoal making machine before, you can certainly benefit from owning one. It may only take a few minutes of your time to locate these businesses. You should also evaluate them based upon where they are located, how much they charge, and what type of output they are capable of. By using these materials, or selling them to the highest bidder, this can be beneficial for all involved. Instead of wasting rice husks, or simply using them for fertilizer, you can instead create a separate source of revenue for your company. More information on biochar equipment for sale here.