Tyre pyrolysis plant manufacturers invite you to visit their facilities to get up close and personal with the equipment they produce. While it’s a good idea to learn as much about the tyre recycling plant, their processes utilize advanced technology and quite a few components. That doesn’t mean that tyre to oil plant is difficult to operate though.

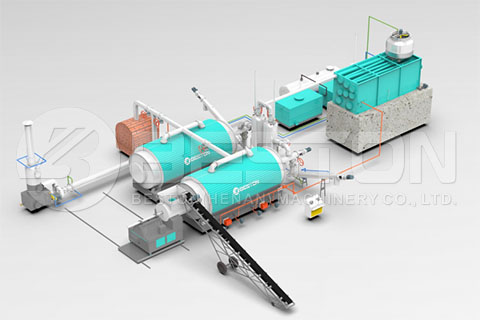

You’re going to find out quickly that these pyrolysis machines run themselves, meaning what you know about them is just an added bonus. Granted, what you do want to do is crunch numbers so that you’re aware of what type of profit you will be making. It’s important to look at the cost of the plant itself and any operating costs. If you were to buy a continuous pyrolysis plant, the operating costs are much lower.

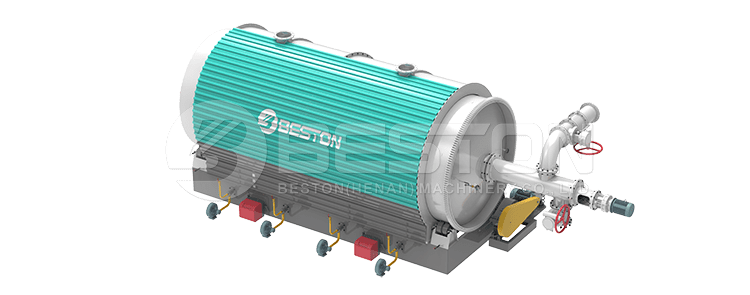

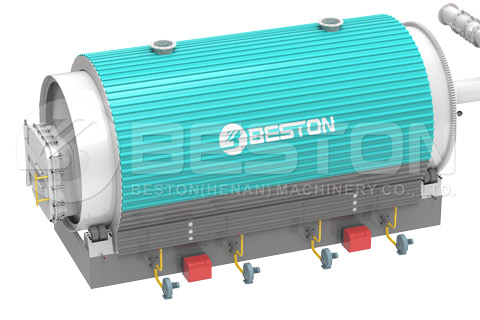

You see, a continuous pyrolysis plant is just going to take care of itself. It runs off the oil that it produces. It’s also much easier to operate than a batch pyrolysis plant, saving you on manpower. That’s exactly what you want to hear, right? Not only that, but it’s going to turn more waste into treasure per day, meaning you have the ability to scale up those profits. More models can be found: https://bestonasia.com/pyrolysis-plant/.

When you are prepared to speak with tire pyrolysis plant manufacturers, you need to ask them what makes their equipment the best. This is where you will learn more about the continuous pyrolysis process and the differences between the machines. Each is built to do the same thing, but there have been many modern innovations.

If you have spoken with other owners of companies that have these plants, you might already know a thing or two about the pyrolysis process. But just wait until you see the advancements in technology that have been made over the last few years. It’s going to pay to dig deeper and find the best pyrolysis plant on the market today.

What do you know about the capacities of tyre pyrolysis plants? You’re going to want to inquire about how much raw waste each tyre pyrolysis plant is capable of converting each day. You want to know your own daily waste output, too, as you want to match up the pyrolysis plant to how many waste tires you have at your facility on a regular basis.

It is possible that you could also turn this into a community effort, helping to keep all of the waste tires out of the landfills. The number of tires continues to increase as the world population does the same. People are putting more mileage on their cars than ever before, and that means worldwide, we are dealing with more waste tires than ever before.

You are going to do something about that, and the method you have chosen is a profitable business. Manufacturers will tell you all about setting up one of these plants and how easy it is to operate. They are going to know the finer selling points and tell you about the latest technologies. You just be sure that you run the numbers so that you purchase the best tyre to oil plant for your operations.