When people think about oil production, they rarely associated it with anything that is environmentally friendly. Indeed, during various stages of oil production, including refining, drilling, and exploration, oil sludge is often found and disposed of irresponsibly. Oil companies used to want to get rid of oil sludge as quickly as possible, as it is full of water and toxic contaminates, which were hard to separate using old technology. Fortunately, pyrolysis plant technology has been used in oil sludge pyrolysis plant, and it has completely transformed the value of such sludge for oil companies, as they can now extract profitable fuel oil from it using a zero pollution generating process. More details can be found: https://mswrecyclingplant.com/oil-sludge-pyrolysis-plant/.

Unprocessed oil sludge should never be sent to landfills or seafills, as it can cause unimaginable damage to ecosystems and the environment. In a bid to compact irresponsible disposal of oil sludge, government bodies in many countries, as well as international environmental protection organizations and private charities, are offering businesses incentives to start dealing with oil sludge responsibly. As a result, investments in modern oil sludge pyrolysis plant technology have never been higher. With the latest pyrolysis machines, oil sludge can be converted into profitable commodities without the production of any toxic emissions.

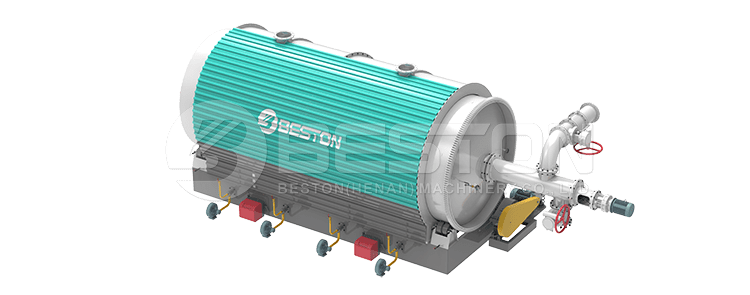

A continuous pyrolysis plant is fitted with automatic feeders and discharging units. This enables the machines to run round-the-clock and process a lot more oil sludge than plants operating in batch working mode. Oil gases of varying viscosities are produced in the pyrolysis reactor before being condensed into liquid form using recycled water cooling systems. Any toxic gases and wastewater produced during the process are sent through a series of other specialized machines to guarantee no harmful emissions from the plant.

The newest oil sludge pyrolysis plants are equipped with advanced safety features, such a pressure gauges, early alarm warning systems and much more to guarantee safe operation and safe working conditions for any manual workers in a treatment plant. The truth is that pyrolysis technology has been revolutionary in its contribution to helping oil producers become more eco-friendly. With the technology, oil producers can harvest extra profits from oil sludge and thus become deterred from sending the sludge to landfills and seafills. Without technology, it was unprofitable for oil companies to attempt to extract fuel from sludge.

Some of the main components within an oil sludge pyrolysis plant configuration include a pyrolysis reactor, oil tanks, gas tanks, water-cooling condensing system, de-casting system, hydroseal, and distillation machines. Pyrolysis plants are generally categorized into three main groups: batch, half-automatic and fully automatic. Businesses need to spend time researching which type of plant will be the most beneficial for their business operations as there are lots of different factors to take into consideration.

When it comes to pyrolysis plant price, there is no questioning the fact that manufacturers from China have some of the best price machines. While some people may be wary of buying industrial machinery from overseas suppliers, the truth is that suppliers in Asia can’t be beaten on price or quality.