If you’ve been shopping for a pyrolysis machine, then you know that there are machines available at many different price points. There are a number of factors that can lead to a change in tyre pyrolysis plant cost. For example, you might have to pay more for a machine if you want it to have a higher production capacity.

Since this is a large investment, you’ll want to think carefully about what can impact price. You should make sure you’re comfortable with what you’re paying and that the machine you’ve chosen delivers a lot of value. These are a few of the things you’ll want to take into consideration.

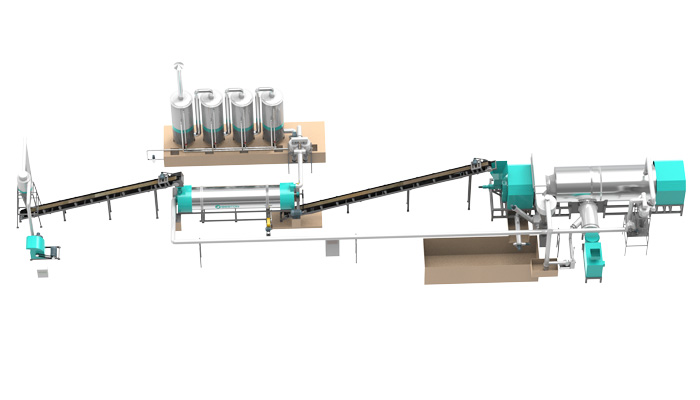

The Size Of The Machine Influences Pyrolysis Machine Prices

It’s common for people to assume that a machine will be more expensive if it’s larger. However, this isn’t always the case. In some cases, the parts needed for smaller machines can be more costly. This can cause these machines to cost more.

Still, it’s clear that the size of a machine can have a big impact on its costs. You should look at the space you’ll be placing your machine in so that you can determine the best size to purchase. Start your purchase from www.BestonTurkey.com/.

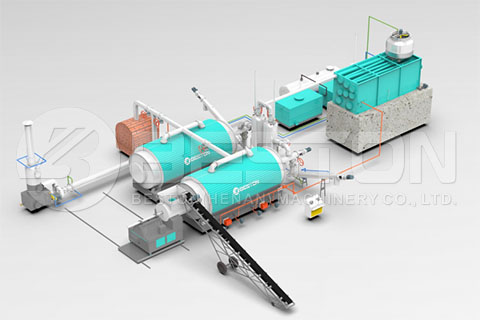

The Capabilities Of The Machine

How much is a pyrolysis machine able to produce in a single day? The more a machine is capable of, the more expensive it is going to be. By the same token, if a machine produces more, you’ll be able to earn more.

Of course, it doesn’t make sense to produce more materials than you need. If you have specific daily production goals in mind, you should try to find a machine that will be able to meet those goals.

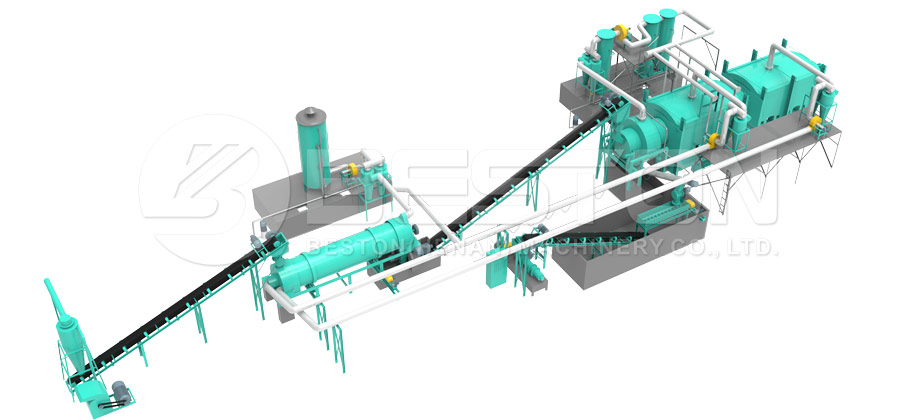

The Features Of A Machine

There are many different features available for these types of machines. For example, a machine can be set to automatically turn off after a period of time so that power won’t be wasted. Many of the machines that are currently available are also equipped with safety features. View more tips https://besseyblog.wordpress.com/.

These features can improve the experience that you have with a machine, but they can also cause you to pay more. Because of this, you’ll want to look closely at a machine’s features to decide whether or not they’re worth paying more for.

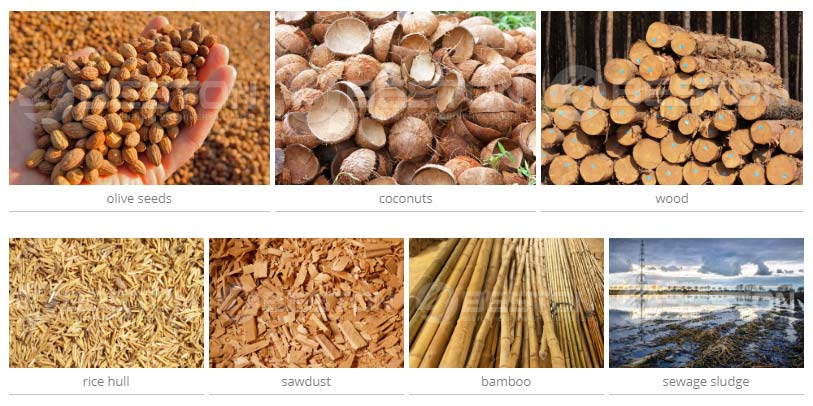

The Vendor for Getting Pyrolysis Machine Prices

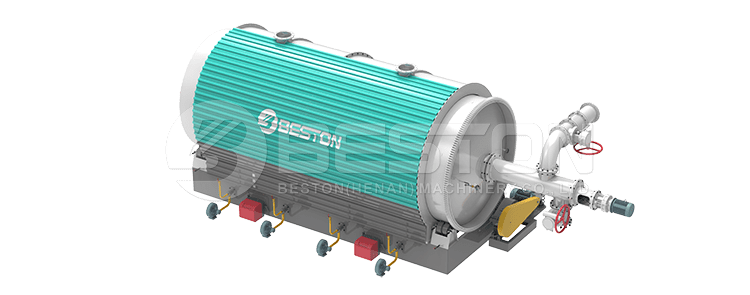

There are few things that can influence your total spending as much as the vendor that you shop with. There are vendors that charge very reasonable rates for their machinery, and there are even vendors that have real bargains. We recommend you find small scale pyrolysis equipment from Beston.

No matter which vendor you work with, you should make sure that you can trust them. You should find a reliable vendor that has a long history of working with customers. You may want to look at customer feedback before you make a purchase.

There are many things that can impact pyrolysis machine prices. If you’re worried about what you’re going to be spending on the machinery you’re buying, the best thing you can do is gather more information. Learn more before you make your purchase, and you’ll have fewer regrets.